Designed to handle coils in diameters up to 24 in., the system from Conair prevents tube damage or unraveling and makes the coils easier to grasp, handle, and move. The roll-fed PP and PET strapping is FDA-compliant for medical tubing applications.

August 26, 2020

A new coil strapping system from Conair for its ATC series tube coilers automatically and securely straps finished coils of small-diameter extruded tubing. Designed to handle coils up to 24 in. (61 cm) in diameter, the system prevents tube damage or unraveling and makes the coils easier to grasp, handle, and move. The roll-fed PP and PET strapping is FDA-compliant for medical tubing applications.

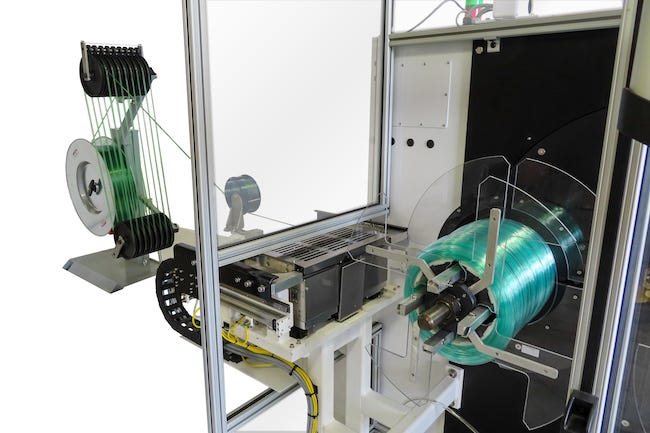

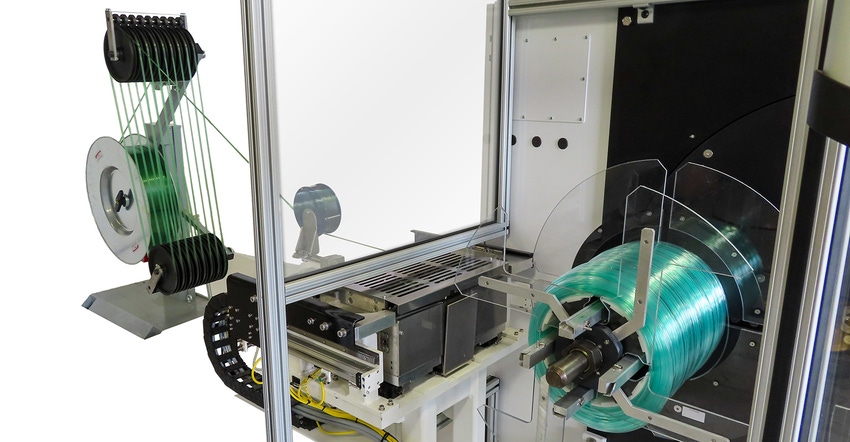

The two-piece system comprises a steel stand that holds two large strapping rolls, positioned approximately three feet from the end of the ATC coiler, and an automatic strapping head unit mounted on a sturdy steel base that attaches directly to the base of the coiler on the coil-outlet side. This consists of a strap guide roller, alignment arm, and combination strap cutter/welder head that affixes, cuts, and welds the strap material onto the coil. The strapping system control integrates directly with the ATC coiler control via a secure Ethernet connection.

|

The two-piece strapping system from Conair comprises a steel stand that holds two large strapping rolls and an automatic strapping head unit mounted on a sturdy steel base on the coil-outlet side. Image courtesy Conair. |

In operation, the strapping system is actuated by a signal from the ATC coiler that a full coil of extruded tubing has moved into position. The alignment arm of the strapping system extends to check the coil position, followed by the cutter/welder head. The head attaches one end of the strap to the tube coil, which rotates until the wrap is completed. Then, the head cuts the strap material and ultrasonically welds the finished coil strap before retracting. Conair notes that ultrasonic welding is a vibratory joining process that does not heat or distort finished tubing. The system can apply one, two, or four straps to a tube coil, based on user selection.

The strapping system is fed by two 12,700-ft rolls of PE or PET strapping material; each roll contains enough material to wrap up to 4,400 coils with one strap or 1,100 coils with four straps. Should strapping material run out, the ATC coiler’s automatic in-line accumulator ensures that tubing production continues while new strapping rolls are loaded. No line shutdown is required.

The strapping system is available as a factory option for new ATC coilers or as a retrofit for existing units.

Conair introduced the dual-spindle, automatic cut-and-transfer ATC series coiler in 2013 to provide tensionless, high-speed winding of small-diameter flexible tubing in sizes from 0.040 to 0.5 in. (1 to 12.7 mm) on coils up to 24 in. (61 cm) in diameter. The coiler fully automates transfer of tube winding when a coil is full, eliminating the need for operator involvement or process disruption.

Additional ATC coiler features, including automatic unloading, conveying, and wrapping of strapped coils, are planned by Conair for future release.

About the Author(s)

You May Also Like