August 23, 2022

Japan’s Polyplastics Group will highlight its expanded engineering thermoplastics portfolio and material supply capabilities at the upcoming K 2022 exhibition in Düsseldorf, Germany. The company will discuss the latest developments in its Duracon POM, Laperos LCP, and Topas COC product lines, which address demanding end-use requirements in the medical, electrical/electronics, and automotive industries.

With full acquisition by Daicel in 2020, Polyplastics has expanded its options for growth and geographical market coverage. The company has increased liquid crystal polymer (LCP) sales to Europe, the Middle East, Africa, and the Americas while making timely investments in capacity to better respond to market growth.

German tech center supports EU customer base

Polyplastics’ Technical Solutions Center in Raunheim, Germany, officially opened in April. The one-stop shop serves the technical support needs of its growing customer base in Europe. “This investment reaffirms our continued commitment to the engineering plastics market in Europe,” said Yohei Iizuka, Managing Director of Polyplastics Europe GmbH. “The new technical service operation will support application development work and enable our customers to shape their innovations from concept to commercialization.”

The company has installed an injection molding machine to facilitate customer molding trials, improve processing issues, and support application development and other collaborative projects. A new showroom showcases Polyplastics’ leading-edge technologies, advanced concepts, and new materials. The showroom also provides space for customer seminars.

New POM plant in China

At K 2022, Polyplastics also will highlight its expanded global supply capability, which includes planned construction of a new polyacetal (POM) manufacturing plant in Nantong Economic Development Zone, Jiangsu Province, China. Production capacity of 150,000 tonnes/year is planned over two stages. The new capacity will satisfy growing demand for POM, improve lead times, and reduce transportation costs. The initial startup of 90,000 tonnes/year of capacity is anticipated in November 2024.

Polyplastics’ LCP business — buoyed by strong growth in electrical/electronics — plans to construct a new polymerization plant with production capacity of 5,000 tonnes/yr at Polyplastics Taiwan. In recent years, LCP market demand has increased because of growing investment in 5G equipment. LCP applications are expected to continue to expand with the full-scale adoption of 5G and millimeter-wave devices. Polyplastics is now offering Laperos LCP globally.

Medical drives COC growth

Polyplastics also will highlight the strong growth of cyclic olefin copolymer (COC), which will be supported by construction of a new production facility in Leuna, Germany. The new plant, to be operated by local Polyplastics subsidiary Topas Advanced Polymers GmbH, will have a capacity of 20,000 tonnes per year, adding significant scope for growth beyond the current output. The facility will be operational by the latter half of 2024.

COC has become a crucial component in many medical devices because of its purity and glass-like properties. Further, in packaging products, addition of Topas COC raises the performance of commodity polyolefins, enabling the development of better recyclable and sustainable solutions.

Regenerated cellulose in LFT resin balances physical properties

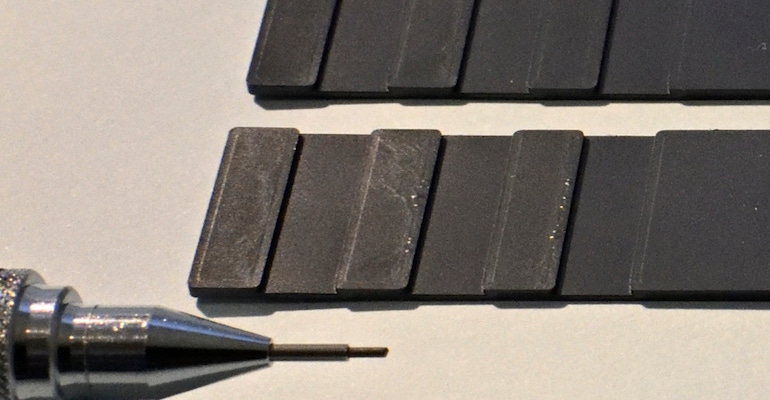

A key recent material development is the introduction of Plastron LFT (long-fiber thermoplastic) resin incorporating specially formulated regenerated cellulose fibers. This eco-friendly Plastron LFT version provides weight reduction plus mechanical strength, enabling manufacturers to reduce their carbon footprint.

Eco-friendly resins that incorporate natural fibers, starch, wood powder, and other plant-based and natural mineral filling materials are being considered for use in a broader range of applications. Cellulose is a promising material to help reduce CO2 emissions, but its insufficient strength is a limiting factor. Polyplastics has addressed this problem by using regenerated cellulose in the development of LFT resins with an excellent balance of physical properties.

In December 2021, Polyplastics acquired a stake in Daicel-Evonik Ltd. from its parent company Daicel Corp., with the name of the joint venture changing to Polyplastics-Evonik Corp. Through this, Polyplastics now supplies polyamide (PA) 12 and PEEK, both available in Asia only.

Visitors to the K show can find Polyplastics at booth B02 in hall 7A.

You May Also Like