The eco-PEN300 dispenser from Preeflow, a ViscoTec brand, was instrumental in precisely and repeatably depositing multiple materials in varying viscosities.

October 8, 2020

Additive manufacturing technology has been used to produce patient-specific heart-valve models. The research project led by the Complex Materials Group at ETH Zurich used medical-grade polysiloxanes in stiff, medium, and soft grades polymerized under UV light. The eco-PEN300 dispenser from Preeflow, a ViscoTec brand, was instrumental in precisely and repeatably depositing multiple materials in varying viscosities.

Based on a patient’s CT scan, a 3D-printed mandrel is produced. Part of the artificial heart valve and reinforcing fibers on the valve leaflets are printed using the eco-PEN dispenser. Other parts of the valve — the intraaortic triangles — are constructed based on a scan of the patient’s aortic root. The silicone is then cross-linked using UV light.

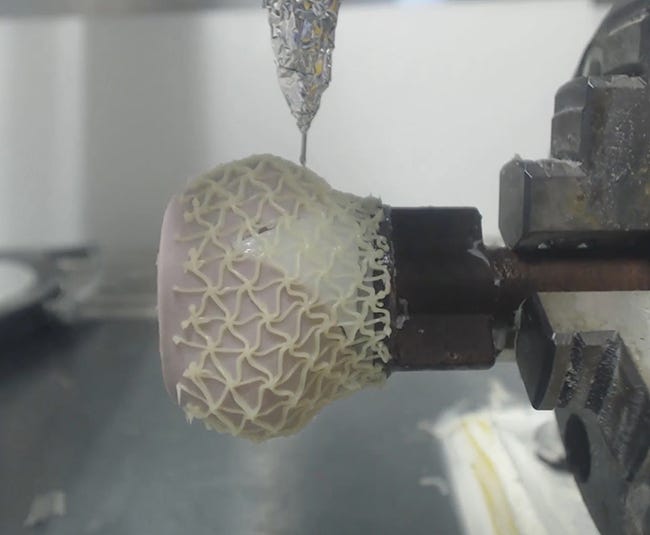

In a second step, a silicone mold of the aortic root is created. An alginate temporarily encapsulates the valve. The cap protects the valve leaflets and allows the creation of an over-hanging artificial vasculature and integrated stent. The assembly is scanned with a one-dimensional laser, creating a virtual surface by which tool paths can be calculated for auxetic stent geometry. The eco-PEN300 is used again to print 0.3-mm-thick struts, allowing the valve mandrel to be removed. The alginate cap is eliminated by means of oven dehydration, resulting in a patient-specific artificial heart valve with a covered or windowed aortic stent, depending on whether or not a coating was sprayed on.

The process is shown in the video.

|

The eco-PEN300 is shown printing the stent structure. The struts are 0.3-mm thick. Image courtesy ViscoTec. |

Through digital fabrication, an artificial valve can be created as a functional implant, according to the researchers. Compared with mechanical heart and tissue valves, this method has several potential benefits:

It enables the production of patient-specific heart valves.

The implants are inexpensive to manufacture.

The materials used may preclude the need to prescribe blood thinners.

The geometry of the printed heart valve is similar to its biological counterpart, as is its functionality.

The fiber-reinforced heart valve exhibits less mechanical stress than conventional implants and features improved hemodynamics.

The eco-PEN300 dispenser is used to print part of the heart valve as well as a stent and ensures the stability of the heart valve and the atrio-ventricular valves, according to Preeflow. This application requires precise, repeatable micro-dispensing in very small quantities, notes the manufacturer.

|

The finished heart-valve replacement system with covered and windowed (left) stents. Image courtesy ViscoTec. |

“The eco-PEN is an excellent extruder when printing with multiple different materials that have different viscosities and rheological properties,” commented Fergal Coulter, who worked on the research project at ETH Zurich. “The [pen’s] precise volumetric dispensing removes variation in flow of the extrudate during long prints and reduces time spent in tailoring pressure profiles to achieve a constant material flow.”

Looking ahead, Coulter envisions integrating stem cells into the valve to match a patient’s morphology. Initial ideas include using cell-loaded hydrogels. One recent project used a Preeflow eco-PEN to dispense living cells to create ventilation slits in sportswear.

About the Author(s)

You May Also Like