January 17, 2018

A team of researchers and engineers at the University of Connecticut (UConn; Storrs) have developed an implantable, biodegradable pressure sensor that could help medical personnel monitor lung disease and other medical conditions. Made of FDA-approved materials, including Poly(L-lactide), or PLLA, the sensor is designed to replace existing implantable pressure sensors that have potentially toxic components. Because the UConn sensor dissolves in the patient’s body after its useful life, it also obviates the need for a second surgical procedure to remove it, reducing medical costs as well as patient recovery time and the risk of infection. The research is published in the current online issue of the Proceedings of the National Academy of Sciences.

|

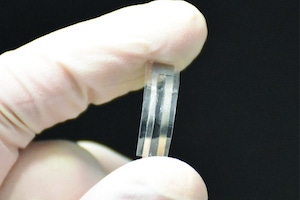

Image courtesy Thanh Duc Nguyen/ |

A prototype sensor made by the lab consisted of a 200-micrometer thick polymer film measuring 5 mm in length and width. The sensor was implanted in the abdomen of a mouse to monitor the mouse’s respiratory rate. It emitted reliable readings of contractions in the mouse’s diaphragm for four days before breaking down into its individual organic components, according to an article published in UConn Today.

To make sure the sensor was also medically safe, the researchers implanted it in the back of a mouse and then watched for a response from the mouse’s immune system. The results showed only minor inflammation after the sensor was inserted; the surrounding tissue returned to normal after four weeks.

A key challenge for the researchers involved getting the biodegradable material to produce an electrical charge when it was subjected to pressure or squeezed, a process known as the piezoelectric effect. In its usual state, the PLLA material is neutral and doesn’t emit an electrical charge under pressure.

Graduate student Eli Curry, lead author of the paper, achieved a breakthrough when he successfully transformed the PLLA into a piezoelectric material by carefully heating, stretching and cutting it in such a way that its internal molecular structure was altered and it adopted piezoelectric properties.

Because the UConn sensor emits a small electrical charge when pressure is applied against it, the device also could be used to provide electrical stimulation for tissue regeneration. Other potential applications include monitoring patients with glaucoma, heart disease and bladder cancer, according to the researchers

“We are very excited because this is the first time these biocompatible materials have been used in this way,” said Thanh Duc Nguyen, the paper’s senior author and an assistant professor of mechanical and biomedical engineering in the Institute of Regenerative Engineering at UConn Health and the Institute of Materials Science at the Storrs campus.

“Medical sensors are often implanted directly into soft tissues and organs,” Nguyen told UConn Today. “Taking them out can cause additional damage. We knew that if we could develop a sensor that didn’t require surgery to take it out, that would be really significant.”

About the Author(s)

You May Also Like