More than 100 companies, specializing in everything from micromolding to robotics, are scheduled to exhibit at the virtual MD&M | BIOMEDigital event on April 6 and 7. Here’s a sneak preview.

March 23, 2021

More than 100 companies that supply leading-edge products and services to medical technology and biotechnology OEMs are scheduled to exhibit at the virtual MD&M | BIOMEDigital event next month, and more are signing up every day. Attendees will have an array of opportunities to network with companies specializing in automation, component engineering, critical fluid control products and engineering, hydrophilic coatings, ISO certification, micromolding, and more. Taking place on April 6 and 7, the virtual event is produced by Informa Markets – Engineering, which organizes North America’s two largest medical manufacturing events — Medical Design & Manufacturing (MD&M) and BIOMEDevice — and publishes PlasticsToday.

Like many industries, the medical device and biomedical sectors have been greatly impacted by the pandemic, revealing a critical need to inject more advanced technologies into the supply and value chain in order to maintain market growth, projected to surpass $800 billion by 2030. “This year, especially, it is essential for manufacturers to continue connecting with biomed device engineers, innovators, decision-makers, and buyers investing in new solutions,” said Hayley Haggarty, Group Event Director, MD&M | BIOMEDigital. “We’re thrilled to host such a strong roster of exhibitors that are laying the foundation for market growth.

“We’re committed to serving this agile community that is driving frontline product innovation,” continued Haggarty. “Our mission with the all-new digital event is to expand partnerships that will further advancement of life-saving medical devices and technology.”

Click here to register for the event and access the expo floor. You can preview the digital venue here.

A selection of exhibitors and a preview of the products and services they will be featuring at the event follows.

|

B9Creations will highlight new biocompatible materials for its additive manufacturing platforms at the event. |

B9Creations is launching a slate of new biocompatible and engineering materials for its line of high-precision additive manufacturing platforms. The materials include BioRes silicone, offering a combination of biocompatibility, high precision, surface finish, and tear resistance; Resilient silicone for parts that need to withstand flexing, compression, and bending; and BioRes – Microprecision, engineered for detailed miniature parts with thin walls and features.

BioInteractions will feature TridAnt Infection Prevention Infrastructure at its virtual booth. BioInteractions said that it has collaborated with Phoel to combine their expertise and create the world’s most advanced infection prevention infrastructure. The use of rapid testing, as well as vaccines, requires additional support from technology to enable these areas to develop fast and effectively enough to keep up with future risks. TridAnt technology targets germs and kills 99.999% of bacteria and viruses for up to 365 days, according to BioInteractions. TridAnt technology works in conjunction with rapid testing and vaccines to provide a complete protection structure against COVID-19, its mutations, and the possibility of future pathogens. The infrastructure can be applied safely in schools, restaurants, hotels, and hospitals.

Cirtronics will highlight its newly expanded transition to manufacturing (T2M) facility, which seamlessly accelerates the move into full-scale production by providing immediate access to engineers and process equipment. Using the T2M facility increases manufacturing efficiency, improves yield, decreases re-work and shortens time to market, said Cirtronics. It is especially valuable when building complex systems with exacting quality and regulatory requirements, including medical devices that incorporate optical assemblies and lasers, according to the company. Cirtronics is FDA registered and certified to ISO 9001 and ISO 13485.

|

Fully automated conveyor system. Image courtesy Invotec. |

Invotec will show how it helped medical device manufacturers reduce cycle times up to 75% and improve OEE scores by 22.5%, generating more revenue per piece, by shifting from a manual to a semi- or fully automated process. Most importantly, it will demonstrate the thought process behind transitioning from a manual to an automated approach that led to these results.

Integrated Computer Solutions Inc. (ICS) creates sophisticated embedded and touchscreen, voice, and gesture-powered smart devices and products suited for medical device, in vitro diagnostic, scientific software, and in-vehicle infotainment applications. As connected technologies drive innovation and transform healthcare, ICS helps companies deliver improved patient outcomes and gain strategic advantage through transformational products. ICS recently established a dedicated medical device practice, adding talent with critical competencies to leverage and adapt technology advances and service offerings in the areas of usability design, cybersecurity, AI and robotics, cloud services, and regulatory compliance. ICS’ medtech practice offers end-to-end product design and development with UX and visual designers and software engineers that utilize ISO 13485–compliant platforms and processes leading to a 510(k) submission.

Performance Motion Devices reports that it will launch its new family of ultra-compact, intelligent motion control amplifiers at the MD&M | BIOMEDigital event. The ION/CME N-Series are compact, PCB-mountable intelligent drives that provide high-performance motion control, network connectivity (Ethernet, CAN, serial, and SPI), and amplification. They feature high power density (up to 1,000 W) in a patented ultra-rugged form factor. N-Series IONs drive brushless DC, DC brush, and step motors, and perform profile generation, servo compensation, stall detection, field-oriented control (FOC), electronic camming, and many other motion control functions. An all-in-one design approach allows the creation of fully custom multi-axis motion control boards in weeks.

Pipeline Design & Engineering develops turnkey equipment, custom fixtures, and automated machines that characterize, inspect, assemble, manufacture, and perform verification testing on devices. Pipeline’s semi-custom nested device holders offer a convenient off-the-shelf solution for R&D and manufacturing teams to hold their devices in fully constrained, zero-play, unambiguous locations, facilitating accurate and repeatable process operations such as testing, inspection, and assembly, said Pipeline. Nested device holders are available in a variety of sizes to accommodate specific devices and can be customized with mounting hole patterns and tool-free fasteners to match specific needs. 3D printed with a special carbon-fiber material, the device holders are nearly as strong as those made in aluminum and can be produced in days instead of weeks at a fraction of the cost.

Ray Products is a full-service custom thermoforming company that has been providing customers with unmatched quality, precision, and dependability for more than seven decades. Continuously investing in its 48,000-sq-ft facility, Ray Products is equipped with 6-axis robotic trim and 3D coordinate measurement systems and provides advanced vacuum forming and pressure forming capabilities. At MD&M | BIOMEDigital, Ray Products will highlight the key advantages of thermoforming and break down the process into six steps. The company is certified to ISO 9001:2015.

|

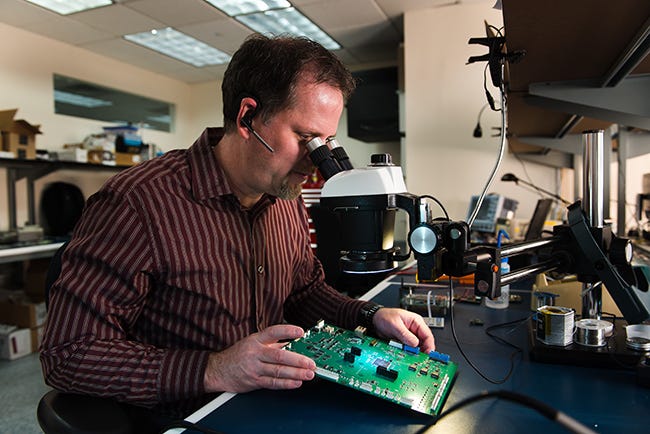

Software and electrical-mechanical design and development are among the core competencies of Sterling Medical Devices. |

Sterling Medical Devices has more than two decades of experience delivering medical device design innovation from concept to market. Core competencies include system, software, and electrical-mechanical design and development; the company also has expertise in regulatory affairs and human factors engineering. Its team of medical device designers, developers, and certified project managers works exclusively on projects in the medical device design and development industry, incorporating current FDA guidelines and regulations, best practices, and the latest tools in the industry for development projects. With a specialization in Polarion ALM, a browser-based regulatory-compliance software program, the Sterling PLM division accompanies customers through the product development lifecycle, offering complete traceability, requirements management, and project management.

Sunrise Labs specializes in the design and development of digital health solutions and complex electro-mechanical systems for medtech and life science applications in an ISO 13485:2016–certified process. The company claims to have built a reputation around solving tough engineering problems and turning novel ideas into commercially viable products. The success of its clients and testimonials demonstrate Sunrise Labs’ strength in software, electronics, systems, mechanical, optical engineering, fluidics, and user experience design. Attendees can look forward to learning about Sunrise Labs’ project portfolio, including solutions for patient monitoring, cardiovascular, dermatology, neurology, IVD, combination products, and connected system applications. The company said it is especially proud to be contributing to products that have a direct impact on patient outcomes related to COVID-19. It is Located in Bedford NH, and has more than 90 employees on staff.

|

Trelleborg Healthcare & Medical will showcase its silicone molding and extrusion expertise at MD&M | BIOMEDigital. |

Trelleborg Healthcare & Medical completed an expansion of its Delano, MN-based manufacturing facility in Q4 of 2020. The expansion included the addition of a 6,000-sq-ft ISO Class 7 cleanroom and enhanced silicone molding and contract manufacturing capabilities. Services performed at the Delano facility extend beyond technical silicone and thermoplastic molding to include assembly and secondary operations, in-house tool making, high-precision machining for micro molding, and automation. The Delano facility is certified to ISO 9001:2016 and ISO 13485 and is FDA registered. At MD&M | BIOMEDigital, Trelleborg said that it is looking forward to showcasing its silicone molding and extrusion capabilities as well as its expertise in combination products.

For more information on the all-new virtual conference and exhibition and to register to attend, please visit the MD&M | BIOMEDigital website.

About the Author(s)

You May Also Like