The technology supports medical device manufacturers in achieving compliance with the European Union’s Medical Device Regulation, which goes into effect in May 2021.

March 3, 2021

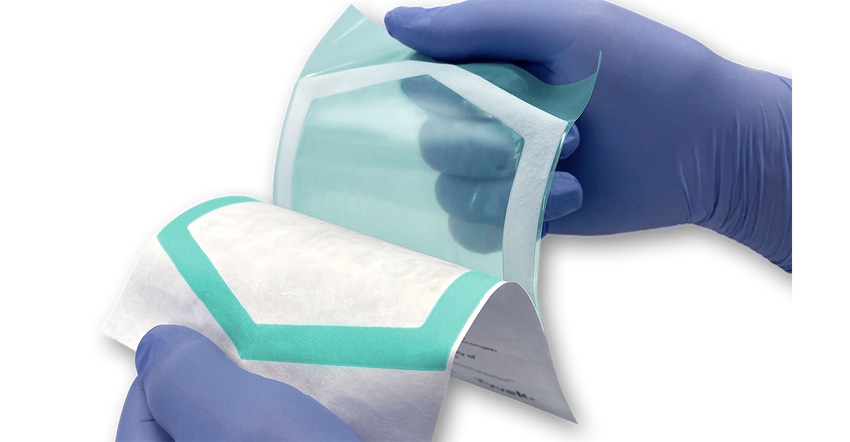

A proprietary visual seal-assurance system is now available for use with uncoated Tyvek. Chameleon technology, developed by Paxxus, changes color once the package has been opened. It supports medical device manufacturers in achieving compliance with the European Union’s Medical Device Regulation (MDR), which goes into effect in May 2021.

The MDR’s General Safety and Performance Requirements stipulate that packaging integrity must be clearly evident to the final user. Chameleon technology allows the end user to readily evaluate the quality of the seal when used with uncoated Tyvek, explained Paxxus. Prior to opening, the seal shows as a darker color when viewed through the film side. Once the package has been peeled open, a vivid colored seal indicator presents on the Tyvek with a contrasting white seal indicator on the film. The package provides a consistent, smooth, fiber-free peel, and the user is able to easily identify any seal flaws. In healthcare settings, this means reduced risk for the patient, said Paxxus in the announcement.

The Chameleon visual seal-assurance system also makes it much easier for manufacturers to conduct 100% in-process seal inspection, according to Paxxus. The inspection process is quick, accurate, non-destructive, and compatible with virtually any vision system.

The unique modified-polyethylene sealant technology was designed specifically to work with uncoated Tyvek. Because the sealant cohesively peels from Tyvek, seal strength is consistent over a large operating window. The stable seal strength simplifies the process validation work required by the manufacturer compared with uncoated Tyvek sealed to traditional PET/PE or Ny/PE materials, according to Paxxus. The cohesive peel also eliminates any fiber-tear concern over the use of uncoated Tyvek.

“We view this innovation as state-of-the-art regulatory compliance,” said Dwane Hahn, Chief Strategy Officer. “The Chameleon system offers an obvious value proposition not only in the manufacturing environment but at the point of use.”

Priced to compete with traditional adhesive-peel PET/PE pouches, Chameleon is available in either nylon or polyester options and can be provided in rollstock form or as pre-made pouches in virtually any color.

Paxxus operates facilities in Addison, IL, Singapore, and Ireland. Manufacturing capablities include blown film extrusion, extrusion coating and laminating, pouch making, slitting, adhesive coating and lamination, and flexographic printing.

About the Author(s)

You May Also Like