A tear in the anterior cruciate ligament (ACL) is the most common knee injury, with approximately 100,000 patients undergoing treatment annually in the United States alone. The standard practice of care typically involves grafting connective tissue harvested from other parts of the patient's body to reconstruct the ACL. Drawbacks include painful and relatively lengthy recovery time. Now, German researchers are investigating the use of a composite material with load-optimized liquid silicone components and a braided 3D structure to treat the injured ACL.

July 8, 2015

A tear in the anterior cruciate ligament (ACL) is the most common knee injury, with approximately 100,000 patients undergoing treatment annually in the United States alone. The standard practice of care typically involves grafting connective tissue harvested from other parts of the patient's body to reconstruct the ACL. Drawbacks include painful and relatively lengthy recovery time. Now, German researchers are investigating the use of a composite material with load-optimized liquid silicone components and a braided 3D structure to treat the injured ACL.

The Institute of Plastics Processing (IKV) in Industry and Skilled Crafts at RWTH Aachen University, both located in Aachen, Germany, have launched a research project to study the use of this composite structure as an ACL implant. The research will examine the production feasibility and the specific properties of an artificial ligament of this kind. The University Clinic of Aachen and Institute of Textile Technology at RWTH Aachen University also are participating in this project.

The Institute of Plastics Processing (IKV) in Industry and Skilled Crafts at RWTH Aachen University, both located in Aachen, Germany, have launched a research project to study the use of this composite structure as an ACL implant. The research will examine the production feasibility and the specific properties of an artificial ligament of this kind. The University Clinic of Aachen and Institute of Textile Technology at RWTH Aachen University also are participating in this project.

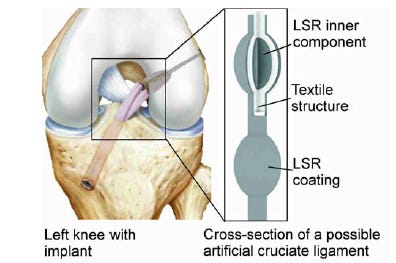

The biomimetic ACL comprises a silicone core, a 3D braided structure and an external silicone coating. The injection molded silicone core is braided on a hexagonal braiding machine, after which a silicone coating is overmolded onto the implant. The implant's three-part design ensures that it will have the required elasticity, stability and torsional stress resistance. Samples of some ligament variants subsequently will be examined in vitro.

The research team hopes that an ACL implant made from a liquid silicone composite structure will enable a reduction in surgery time and allow the surgeon to adjust the length, diameter and load of the implant to suit individual patient needs. The biocompatible overmolding of the braided system should also overcome the limitations of other synthetic ligaments in terms of torsional and abrasion stability, say the researchers.

The project began in January 2015 and is expected to be completed within the next two years.

About the Author(s)

You May Also Like