Counterfeit drugs reportedly kill more than 700,000 people annually, and there have been reports of a rise in bogus medical devices, as well. To combat this alarming trend, researchers at the University of Michigan and in South Korea have developed a technique that reveals a hidden image in labels when they are breathed on, allowing users to authenticate a product.

August 6, 2014

Counterfeit drugs reportedly kill more than 700,000 people annually, and there have been reports of a rise in bogus medical devices, as well. To combat this alarming trend, researchers at the University of Michigan and in South Korea have developed a technique that reveals a hidden image in labels when they are breathed on, allowing users to authenticate a product.

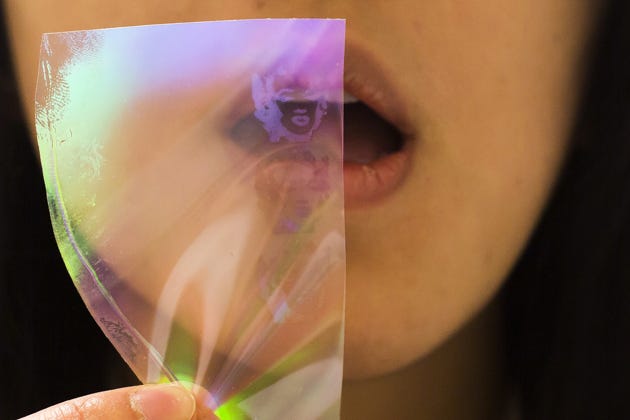

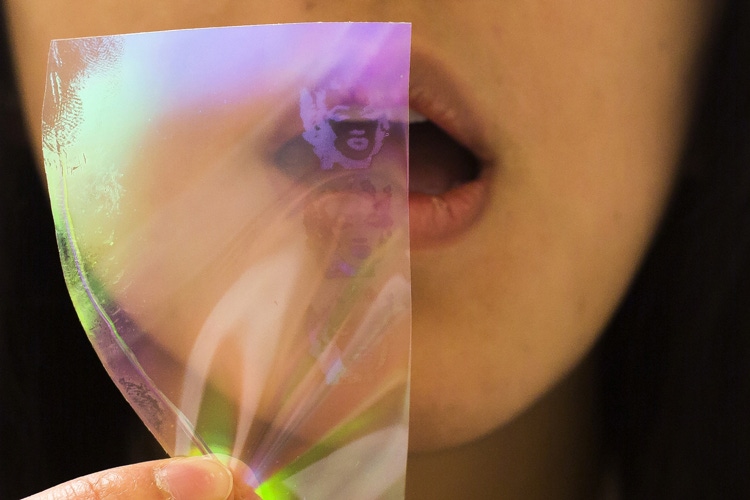

The method involves the creation of tiny features, called nanopillars, that are approximately 500 times smaller than the width of a human hair. The nanopillar array on the surface of a label, which can be plastic, fabric, paper, or metal, hides a text or image. Condensation produced by breathing on the material reveals the underlying graphic.

|

Image courtesty Joseph Xu. |

Producing a template with these features requires sophisticated equipment that, in theory, would be beyond the reach of counterfeiters. Once the template is ready, however, labels can be printed in large rolls at a competitive cost. Molding makes the technology possible at an affordable price point.

Prior to this research, it was impossible to mold nanopillars because the materials from which they were made would stick to the tooling, according to a press release published on the university website. To overcome this challenge, the team developed a special blend of polyurethane and an adhesive.

The liquid polymer fills the mold and shrinks slightly as it cures, allowing the pillars to release. They are also strong enough to withstand the wear that may occur during shipping. The materials typically used for making nanopillars are too brittle to withstand handling.

To demonstrate the technology, doctoral student Terry Shyu, who took part in the research under the leadership of Nicholas Kotov, Joseph B. and Florence V. Cejka Professor of Chemical Engineering, fogged a sample film, revealing the face of Marilyn Monroe, as shown in the video embedded below.

Packaging applications for drugs and other products that are sufficiently lucrative to attract counterfeiters would benefit. Medical devices may also be an area to explore, although possible sterilization issues will need to be resolved.

The university is pursuing IP protection and has put out a call for commercialization partners to help bring the technology to market.

This research has been published in Advanced Materials.

About the Author(s)

You May Also Like