The good news is that six out of the top 10 economies in the world are now officially out of recession, measuring small yet sustained growth in their GDPs. The bad news is that the United States isn’t one of them. Japan, China, Germany, India, France, and Brazil have all pulled forward. Both France and Germany reported growth of 0.3% from April-June.

August 31, 2009

The good news is that six out of the top 10 economies in the world are now officially out of recession, measuring small yet sustained growth in their GDPs. The bad news is that the United States isn’t one of them. Japan, China, Germany, India, France, and Brazil have all pulled forward. Both France and Germany reported growth of 0.3% from April-June.

|

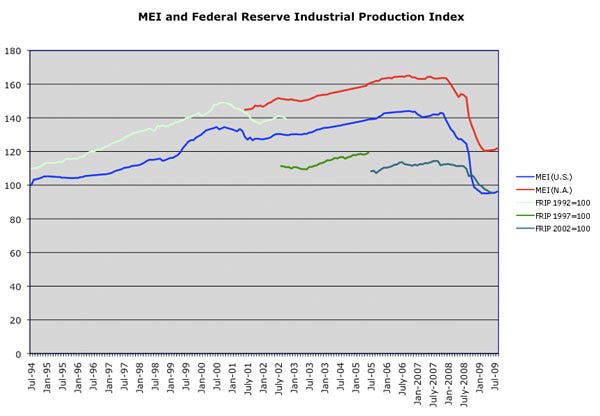

While the United States isn’t out yet, the indicators show positive movement. According to a survey of 102 members of the National Assn. for Business Economics, the U.S. recession is abating, but shows few signs of an immediate recovery. We are leveling off and even gaining some ground, but it will be a few more months before we see growth.

|

The US GDP dropped about 1% in the second quarter, which is a solid improvement from the fall of 6.4% in the first quarter. Bloomberg News asked a panel of 76 economists to project the GDP for the coming quarter. The consensus is about 2% growth each quarter for the next four quarters. Slow, steady, sustained growth is the healthiest recovery and this is a positive sign.

Consumers paying off debt and increasing savings are driving the slower-but-better recovery. July retail sales fell 0.1% after three months of increases. It was most likely driven by fears about unemployment. The rate of new unemployment claims has slowed, but overall unemployment levels continue to increase and will probably do so until they top out at about 10% in early 2010.

|

The government’s grass roots “cash-for-clunkers” stimulus program was hugely successful. Sales at dealerships and parts stores climbed 2.4% in July, the biggest gain since January. The program helped sales at dealerships and parts stores climb 2.4% last month, the biggest gain since January. The program helped to get customers into dealerships. Many of those who did not qualify for the program ended up buying late-model used cars at aggressive prices. Total light vehicle sales for July were just shy of 1 million units, a milestone the industry hasn’t topped since August 2008. The initial $1 billion was spent by about 245,000 consumers from July 1 through August 7, when an additional $2 billion was added to the program.

|

The new housing market remains stagnant while the $8000 first-time-home-buyer tax credits being offered by the federal government continue to be used to snatch up bargains in the existing home market. According to data from the National Assn. of Realtors (NAR), total existing-home sales, including single-family and condo, rose 3.8% in the second quarter, but remain 2.9% below Q2 2008. Thirty-nine states experienced sales increases from the first quarter, and nine states were higher than a year ago. NAR attributed the rise in sales to the increased affordability of homes.

|

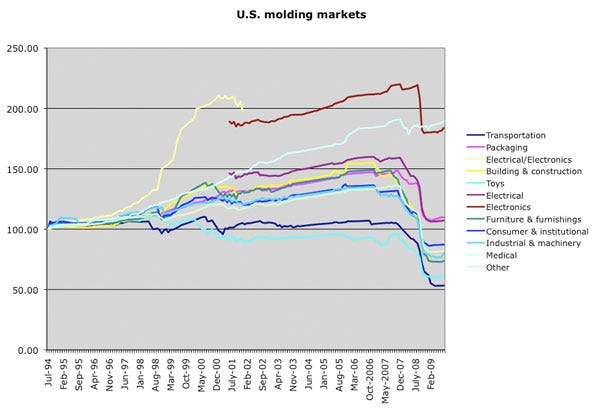

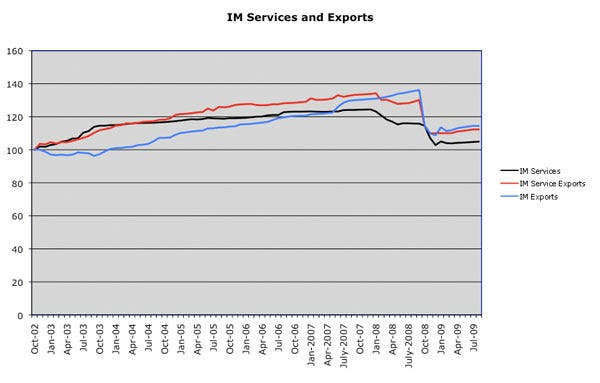

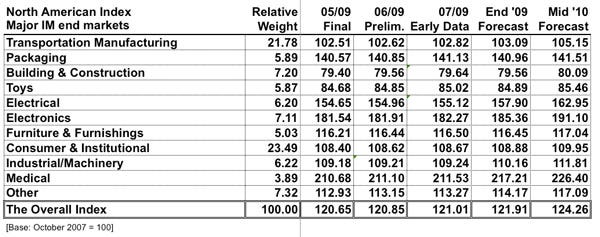

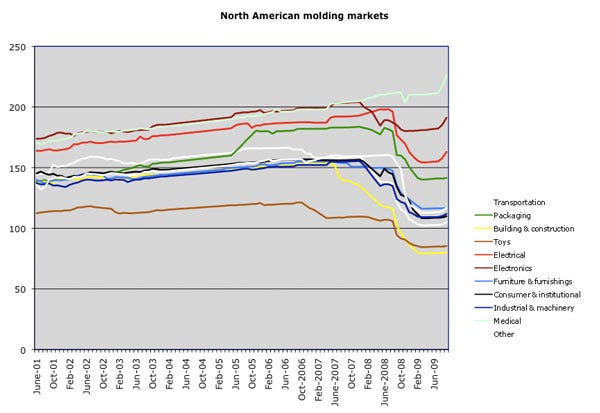

Manufacturing data from the Tempe, AZ-based Institute for Supply Management indicate that the overall economy grew for the third consecutive month, but economic activity in the manufacturing sector failed to grow in July for the 18th consecutive month. The decline in manufacturing was slower in July and new orders rose significantly, which is a solid indicator of future growth in the sector. The report stated, “The New Export Orders Index shows growth following nine consecutive months of decline, suggesting that the global economy is recovering. Overall, it would be difficult to convince many manufacturers that we are on the brink of recovery, but the data suggests that we will see growth in the third quarter if the trends continue.”

|

Planning ahead for health emergencies can save you money

Having an employee who takes time off work because (s)he is ill or because (s)he needs to care for an ill child might not seem like a big deal, but in 2007 it accounted for more than $300 billion in lost productivity in the United States. That’s certainly not chump change and it’s separate from more than $1 trillion in productivity that was lost due to chronic illnesses and injuries. That was an ordinary year. On June 11, 2009 H1N1, also known as swine flu, was declared a pandemic. It is highly contagious, although so far it does not appear to be as deadly as some of the “ordinary” flus covered in the annual vaccines. So how do we plan to maintain productivity in the coming months when we expect lost time will be higher?

Vaccines for H1N1 are in the works. It currently looks like the United States will designate the first doses for school-aged children (who have spread the disease the fastest) and those with specific health problems (who have had the highest mortality rate). The annual flu vaccines will be available earlier this year to allow time because the current swine flu vaccine is a two-part process. The first dose of the swine flu vaccine is followed by a second dose three weeks later.

Reviewing some basics with your staff will help to reduce sick time every year during flu season, regardless of whether you get slammed by swine flu or not. Encourage staff to get annual flu shots plus any special vaccines recommended by your local health department. If your tough guys aren’t willing to go get a shot, remind them that an inhaled annual flu vaccine is available for most healthy people from 5-49 years old. If you have a midsized to large company, talk to your local hospital about hosting a flu vaccine clinic onsite. For smaller shops, make appointments for your staff to have a road trip to a hospital, clinic, or doctor’s office to get vaccinated together.

A few simple steps can help reduce the risk of spreading influenza. Review with your staff the importance of covering their coughs and frequent hand washing with soap followed by thoroughly drying the hands. Be sure you have soap and towels stocked in all the washrooms and in the lunchroom. When someone in your shop falls ill and you suspect it’s influenza, disinfect all surfaces and tell that person to stay home for at least 24 hours after their fever is gone. Having one person miss an extra day is better than having them spread the flu to more staff that will then need time off.

While we’d all like to hope for the best, it’s a smart investment to be prepared for the worst. With that in mind, contact the emergency management office in your municipality for a copy of their pandemic flu protocols. This will let you know what is expected of you and your staff. Every municipality has a plan, but in small towns the emergency manager may be a part-timer with another full-time job. In these cases it can take days or weeks to get a copy.

Use your municipality’s plan as the basis for your company plan. Find out from your staff who will need time at home if schools close for several days. If the municipal plan will require you to shut your shop, will you cancel orders, delay orders, or try to work out a deal with another molder in an unaffected area? If OK for a week? Will products produced during a “sheltering in” period be allowed out of the area and if so, will there be any restrictions on shipping?

No one likes to think about getting sick, but time you spend now could be money you save later.

Lisa M. Pellegrino is a senior advisor of The Repton Group LLC (New York, NY).

About the Author(s)

You May Also Like