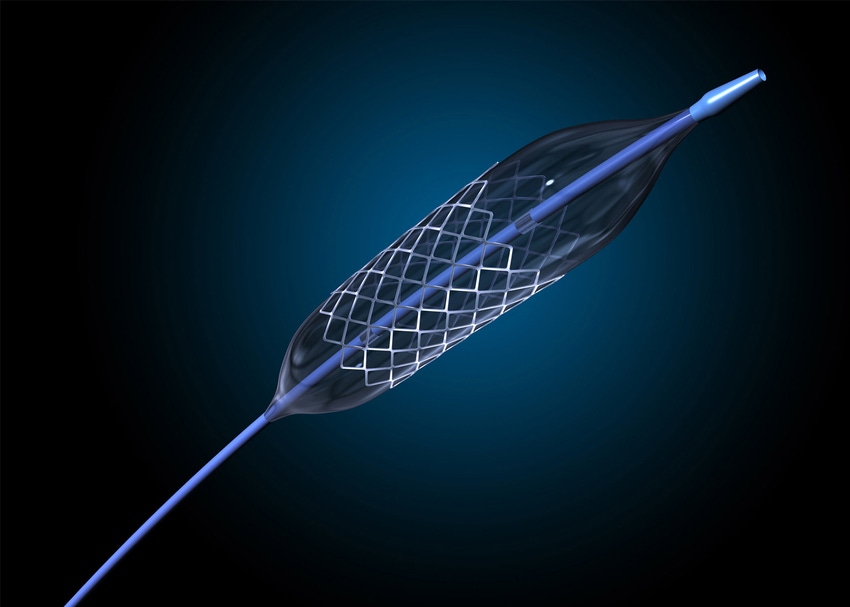

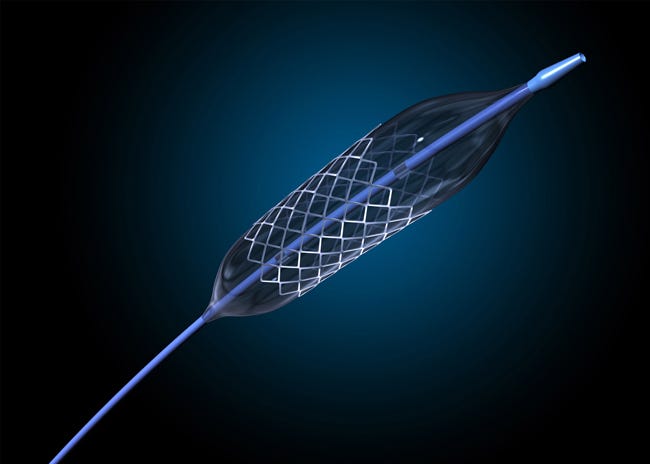

New radiopaque compounds developed by materials supplier Foster Corp. (Putnam, CT) are reinforced with nanoparticles to improve pushability of thin-wall catheters. The LoPro Plus compounds allow for extrusion of single-layer tubes with the radiopacity and strength properties of conventional two-layer tubes. Consequently, medical device manufacturers can reduce material and inventory costs when compared with standard two-layer constructions.

June 6, 2014

New radiopaque compounds developed by materials supplier Foster Corp. (Putnam, CT) are reinforced with nanoparticles to improve pushability of thin-wall catheters. The LoPro Plus compounds allow for extrusion of single-layer tubes with the radiopacity and strength properties of conventional two-layer tubes. Consequently, medical device manufacturers can reduce material and inventory costs when compared with standard two-layer constructions.

Radiopaque compounds typically include 30% to 40% barium or bismuth filler to provide fluoroscopic visibility of catheters within blood vessels. However, the fillers are not designed to improve strength properties, says Foster Corp. Improved pushability and torque for catheters that must reach deep in the body or precise locations often requires coextrusion of additional layers using polymers with high strength properties. Purchase and storage of multiple materials can increase manufacturing costs. LoPro Plus compounds combine these properties in a single material and, thus, may result in a cost saving.

The nanometer-thick reinforcements, which are up to 1500 times their thickness in length, are dispersed throughout the polymer at the molecular level. When added to radiopaque filled compounds in small quantities, the nanoparticles improve rigidity without increasing brittleness, according to Foster Corp. Recent studies performed by the company reportedly indicate that the addition of 3% nanoparticles to a 72-durometer polyether block amide (PEBA) with 35% bismuth filler improves flexural modulus by 60% and increases elongation by 10%.

About the Author(s)

You May Also Like