Everyone wants their children to grow up to be productive members of society; to have a good job and contribute their talents in whatever ways they can. Parents of developmentally disabled children are no different. But in 1965, there were not many options for young people. That's when a group of parents of children with developmental disabilities founded Coarc, a not-for-profit organization and a much better alternative to being placed in an institution.

August 22, 2014

Everyone wants their children to grow up to be productive members of society; to have a good job and contribute their talents in whatever ways they can. Parents of developmentally disabled children are no different. But in 1965, there were not many options for young people. That's when a group of parents of children with developmental disabilities founded Coarc, a not-for-profit organization and a much better alternative to being placed in an institution.

"People really wanted more for their children, other than what the institutions at that time had to offer," said Alex Schneider, director of development for Coarc. "The organization started small, first as a pre-school, then a summer camp, and more. As their children got older, the parents recognized their need for meaningful employment and a paycheck as well." And again they created a solution, this time a non-profit subsidiary called Coarc Manufacturing, a contract manufacturing service that has grown into a successful commercial contract manufacturer, providing assembly, decorating and finishing services, as well as in-house plastics injection molding to a variety of companies.

At first, the organization didn't have molding capabilities, but took in relatively easy work from companies and organizations such as stuffing envelopes and simple assembly work. Today, the company operates 11 injection molding machines ranging from 35-440 tons, and performs a variety of secondary operations. "We do everything from complex assembly to bag and tag items, to cutting, assembling and shipping floor mats that are placed in front of the doors at major department stores," said John Menegio, director of manufacturing.

|

Coarc molds the caps and assembles printer toner bottles for a blow molder. |

"We even do 8' x 4' collapsible trade show display racks that require riveting and drilling, and two versions of an eye wash tank for first aid stations. One requires spin-welding, another is assembled using different fixtures, then we leak test everything," Menegio added, describing the more complex tasks that the employees perform today. Coarc also does electrical work that includes wiring, soldering and assembling whole house fan units. Coarc's ideal customer is one that needs injection molded parts that require assembly. But proud of its flexibility, Coarc makes many different types of products.

Tom Vantassel, manufacturing engineer, commented that Coarc takes in a lot of overflow molding and various types of assembly projects from local molders. "We mold wire spools for a local molder as well as filter cores for them," Vantassel said. "We also mold slides and caps for a local blow molder that molds toner bottles for Xerox, Kodak and Konica Minolta. We do some medical products such as disposable needles used in testing for allergies, and a scale tray for a company in Pennsylvania. Working for a local molder, we also mold detergent bottle caps for small bottles to be vended in a coin-operated laundry."

Management at Coarc goes the extra mile to help each of the 125 employees with disabilities achieve their highest potential. "We have some people who have a high level of ability and are very productive, and some of them are training to work in the community," said Bruce Drake, associate executive director. "But we also have people with lower capabilities who wouldn't be able to work without the help that we provide to enable them to do their jobs."

Employees of Coarc are given jobs that suit their level of ability. "Depending on their level of ability they might struggle with a certain task," Drake explains. "To help them do the job we can design jigs and fixtures that enable them to accomplish the task. We don't need things to be cookie cutter for our employees. We can create a custom system for them that fit with their product. Likewise, when a company has an unusual molding and assembly job we can design a production system that is a custom fit using our company's capabilities and expertise, because we do that every day."

Coarc Manufacturing is currently almost 100% self-sustaining. "We do get some funding but that is going away," Drake said. "There are plans in place for the elimination of those funds both at the state level and at Coarc. Our goal is to ensure that when funds are gone, we'll be self-sufficient."

While Coarc Manufacturing's social mission is to provide employment opportunities for people with developmental disabilities, the parent organization's mission includes providing funds for other services for their employees. "Those 125 people we employ are transferred to and from work by Coarc," said Drake. "New York State mandates formal background checks for our people who work with the developmentally disabled so funds go to providing these as well."

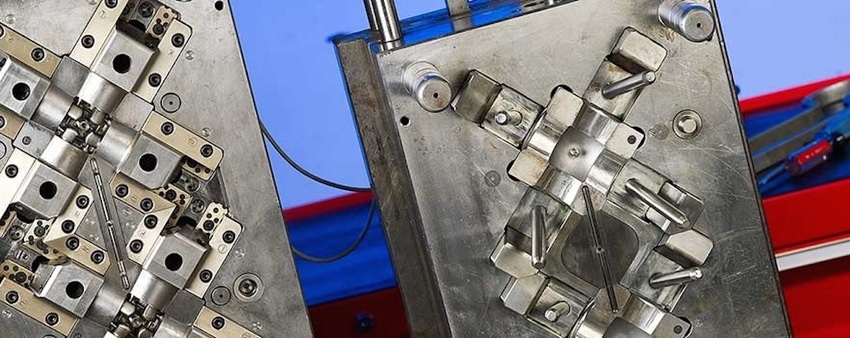

|

Coarc's molding work ranges from relatively simple shapes to complex, close-tolerance parts. |

The only problem that Coarc has with its business model is that it's the best-kept secret in the state of New York. The organization's management is in the process of spreading the word that Coarc Manufacturing is a proven top-notch supplier. "Once they find out about us and what we provide here, customers love Coarc, but not enough know about us," Drake said. "However, we're getting an active sales force and will be hitting trade shows. We have a great mission in serving great people with disabilities, and equally important, we also provide great molding and production services at a great price."

Alex Schneider concurs: "Coarc Manufacturing fits in well with our agency's mission, to expand abilities one person at a time. And that meshes with our focus on the customer. We perform every job individually - one customer at a time. Anything anyone comes to us with, we find a way to make it work so that everyone is a winner."

About the Author(s)

You May Also Like