Leading automotive plastics component supplier Mecaplast (Monaco) believes it can cut the weight of interior and exterior trim parts by between 30% and 50% by using a newly patented injection molding processing technology in combination with novel polypropylene compounds.

June 12, 2012

Leading automotive plastics component supplier Mecaplast (Monaco) believes it can cut the weight of interior and exterior trim parts by between 30% and 50% by using a newly patented injection molding processing technology in combination with novel polypropylene compounds.

Mecaplast is about to embark on a French government-sponsored project called Plume (French for "feather") to industrialize the process, which relies on a combination of moving mold cores, a chemical blowing agent, and lightweight reinforcing fillers. The project starts in September, and will run for two years. It will have a total budget of €2.4 million ($3 million).

|

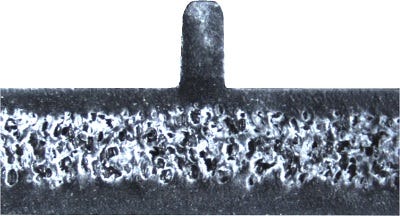

Moving mold cores, a chemical blowing agent, and lightweight reinforcing fillers combine to save up to 50% in part weight. |

The project will also involve the participation of several other French-based companies: Japanese compounder Sumika Polymer Compounds (Saint-Martin de Crau); mold-maker Cero (Nantes); polymer science research laboratory IMP at the University of Saint-Etienne; and Cemef (Sophia Antipolis), a research laboratory with expertise in process simulation.

"Incorporation of parts made by the Plume process could lead to a total vehicle weight reduction of between 5 and 7 kg," says Elsa Germain, Research and Innovation Engineer at Mecaplast. "This will have an important knock-on effect on fuel consumption, with resulting carbon dioxide emissions falling by around 0.5-0.7 g/km."

The process is similar to one already used in Japan for production of parts used by such automotive companies as Honda and Toyota. However, that process has some limitations, especially in terms of surface finish, since the parts are made with talc-filled polypropylene (PP). The Plume process will use newly-developed compounds that contain little or no talc.

Instead, they incorporate Hyperform synthetic mineral-based reinforcing fibers from Milliken (Spartanburg, SC) that not only yield improved surface quality but also help reduce part weight by as much as 7%, without loss of mechanical properties. Previously Mecaplast had reported development work using such fillers. Compounds containing a combination of Hyperform with various other fillers will be trialed during the Plume project.

The new compounds, which are based on PP impact copolymer and are being developed exclusively for Mecaplast, also have very good flow properties. Melt flow index is over 50 g/10 min. This is critical for the success of the Plume process.

In the Plume process, material is injected into a mold with moving walls that are initially in the forward position. Once all the material has been injected, and the skins of the part have solidified, the walls retract. This lowers the pressure in the mold cavity, and chemical blowing agent, until now dissolved in the melt, comes out of solution in the areas of the part that are still fluid to create a cellular structure that fills the newly created space. The foaming process on its own (disregarding compound formulation) enables a weight reduction in the part of at least 30%, compared to a conventional solid molding.

Cemef will look at melt rheology and its effects on the process and it will also carry out analysis of the microstructures created by the chemical foaming. IMP-UJM will study the mechanical behavior of parts made under various conditions.

Mecaplast plans to trial the process on two components, a tailgate interior trim and exterior beltline moldings. The beltline moldings will be produced in two versions, one with a grained surface that will require no painting and another that will be paintable. —[email protected]

About the Author(s)

You May Also Like