LCD displays are becoming ubiquitous in all manner of electronic products from smartphones through to large-screen TVs and as such, processors with capabilities in light guide panel and diffusion sheet molding are enjoying good business volumes. But like many molding jobs that processors take on, there is constant pressure to cut costs.

October 26, 2011

LCD displays are becoming ubiquitous in all manner of electronic products from smartphones through to large-screen TVs and as such, processors with capabilities in light guide panel and diffusion sheet molding are enjoying good business volumes. But like many molding jobs that processors take on, there is constant pressure to cut costs.

|

All-electric Toyo press proves PS a worthy optical plastic for LCD applications. |

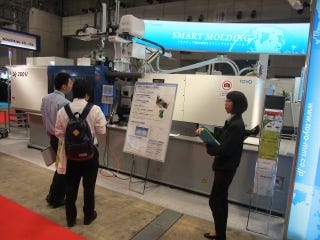

One solution on the horizon is to employ a lower cost resin than the polycarbonate, acrylic, or more exotic plastics such as cyclic olefin copolymer that are typically currently employed. That's exactly the solution being proposed by Toyo Styrene Co. (Tokyo), which teamed up with injection machine vendor Toyo Machinery & Metal Co. (Akashi, Japan) to demonstrate the applicability of an optical polystyrene (PS) grade in the molding of 10.1-inch light guide panels at the IPF Show in Japan.

A Toyo Si-280V GD620 all-electric press demonstrated molding of PS light guide panels in a two-cavity tool cycling at 40 seconds with each panel weighing 21 g. The press is capable of an 800-mm/s injection speed at peak pressure of 350 MPa. Toyo employed the services of a Chinese toolmaker, Dongguan Nissin Plastic Products Co. (Guangdong) to fabricate the mold in a further cost-cutting initiative.

Besides lower cost, the PS grade employed reportedly absorbs less moisture, warps less, and has better dimensional stability than competing resins according to Katsumi Kidokoro, General Manager of the Technical Division at Toyo Styrene. "Low warpage is particularly important in LCD modules because the light guide panel is typically laminated with polyester sheets. If warpage is present, this leads to scratching of the panel due to differences in linear thermal expansion." -[email protected]

You May Also Like