We’re now seeing nuances of reusable, refillable, returnable packaging, as well as bio-based alternatives to plastic packaging.

Sustainable packaging has been a priority for brand owners for more than a decade. As 2021 advances, we see relevant and effective activities that address the consumers’ hunger for brands that show respect for the environment.

The consumers’ increased awareness continues to drive the sustainable packaging mission of brand owners. Around 74% of consumers say they are willing to pay an additional amount for products in sustainable packaging. Recyclable packaging seems to matter most to consumers because recycling is something they can do to contribute. However, in many areas, the business of recycling is struggling. This may force brands to adopt other sustainable packaging options.

“Like what?” you may ask.

Here are seven sustainable packaging trends we’re seeing in 2021.

1. Refillable parent packaging.

The use of refillable containers supports Zero Waste initiatives. It functions on a simple principle: The store provides products in bulk, and customers bring their empty refillable containers and fill them with product (see image above). Cleaning and personal care products are often available this way.

Leslie Campbell, the owner of Sustain LA, explains her mission of zero waste: “Zero Waste has many aspects. The main concerns are: What we are throwing away? How to conserve resources? How to restore the natural process of the planet? Recycling plastic is a solution, but unfortunately, less than 9% of the plastic is recycled.”

The use of refillable containers reduces the transportation and manufacturing costs, but the success of this system relies on multiple factors. This may include; acceptance from general public, additional cost incurred on supply chain, and availability of containers in large quantity.

2. Bulk dispenser refilling.

While similar to retailer-to-consumer bulk buying in refillable containers, bulk dispenser refilling is another packaging trend for the wholesaler-to-retailer market. The trend is rapidly expanding in the USA, Canada, Europe, Indonesia, Brazil, and South Africa. The wholesalers request retailers to bring their container and fill it up.

The concept is being adopted by a limited number of wholesalers and for a limited number of products. However, retailers like Asda and Waitrose are providing a number of products to consumers in bulk dispensers — mainly dry products, like cereals, pastas, and nuts — which need refilling themselves. This trend is expanding rapidly, and general stores and smaller grocery chains are also adopting it for its contribution to environmental sustainability.

Algramo, a Chile-based consumer brand, sells bulk products at an affordable cost in lower-income areas to increase its usage across the region.

3. Returnable/reusable packaging.

Returnable/reusable packaging is not a new concept in the business-to-business market. Manufacturers have long reused crates, drums, pallets, and bulk containers.

This returnable trend has returned, with a number of organizations using returnable containers and cutlery items to reduce environmental impact.

CupClub (UK), Globelet (Australia), ReCup (Germany), and CupKita (Indonesia) are pioneers. But the trend is not limited to liquid drinks: Fresh Bowl (US) uses a glass container to serve a fresh salad. The container can then be returned to its kiosk.

As another example, this one for industrial products, Oshkosh Corp. is a giant wholesaler that has adopted the trend and uses returnable packaging. Returnable packaging management software is also available to manage assets through the supply chain.

In 2021, the reusable packaging concept is being embraced by the business-to-consumer market, too.

Major organizations like Nestlé, P&G, PepsiCo, and Unilever are adopting the trend by supporting the Loop circular economy shopping platform, initiated by Tom Szaky, founder and CEO of TerraCycle.

“Consumers are delivered their favorite products in sustainable and transit packaging. They use it and return it for reuse,” Szaky told CNN. “It was tough to ask consumers for a change, as plastic containers are more convenient for them. But we did, and Nestlé was the first to be a part of the program.”

Loop is growing at a healthy pace. It was initially available in three cities and offered 300 products. Since then, it has expanded nationwide in America.

4. Antimicrobial packaging.

Antimicrobial packaging is a newer example of how packaging contributes to sustainability by helping to reduce product waste. However, the development of such packaging is generally expensive and could require major design changes.

Industry expert Hayriye Unal from Sabanci University, Turkey, came up with an innovative idea of creating an antimicrobial film using clay. This film used for packaging will reduce the microbial and ripening activities on food, keeping it fresh for a longer period.

Unal explains, “Using antimicrobial packaging is beneficial in keeping food fresh for a longer period. Along with this, the reduced microbial action will reduce the potential of viral or microbial diseases proportionality. It is prepared from biodegradable clay.”

5. Edible films.

Edible packaging is finally available for commercial purposes. Different natural products can create edible packaging, but the most effective one is chitosan. It is a polysaccharide that possesses natural antibacterial activities and is present in ample amount.

Two reasons for using chitosan packaging are that it’s edible and can protect food from multiple mechanisms. It serves as a physical barrier and prevents the direct contact of microbes with the food. It also inhibits the respiratory activity of bacteria by blocking the oxygen supply in the packaging.

The edible films are used for fruits and vegetable packaging. But food scientists believe that by the end of 2021, it will be adopted by restaurants for packaging takeaways.

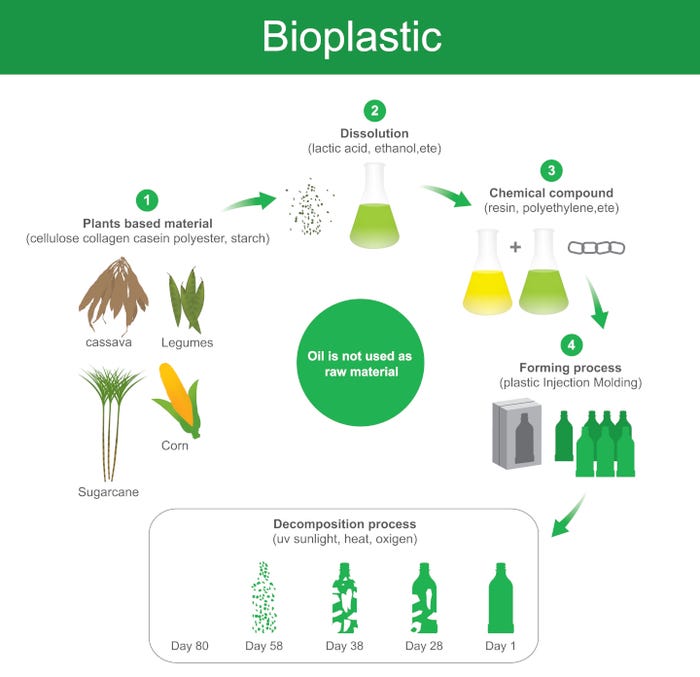

6. Bioplastics.

Bioplastics are prepared from biodegradable, renewable resources such as starch, proteins, and polylactic acid (PLA). The number of available products and suppliers has exploded in recent years and bioplastics are being used today in commercial markets across the globe.

Polyethylene terephthalate (PET) has the highest recycling rate of all the plastics used for packaging. It is typically produced from feedstocks but it can replace some of its petroleum-based components with bio-based alternatives.

According to the European Bioplastics, bio-based PET is a relevant, economic, and effective form of plastic packaging. It contains an elastic texture with strong fibers that makes it suitable to replace other packaging materials for containers, rigid bottles, and films.

Klaus Hartwig, the head of Nestlé research center, elaborates on the company’s 100% renewable plastic bottles for mineral water packaging. “We are using PET. It is recyclable and has better environmental performance. We want to make it big, fast, and cost effective,” Hartwig says.

The materials used for the packaging will not compete with a food source. The raw materials are already waste or by-product, such as rice hulls and wood chips.

7. Post-consumer recycled resin.

Post-consumer recycled (PCR) resin is a recycled plastic used for making packages like water bottles, sheets, films, and other containers. PCR is now in high demand as many companies have set goals for PCR content in their packaging. Industries rapidly adopting it include electronics, retail, pharmaceutical, and medical packaging.

Stephanie Baker, owner of the world’s largest recycler, KW Plastics, tells us, “We purchase recyclable plastics from the surrounding areas and create recycled packaging material. Our 90% of raw material comes from bottles used in kitchens and bathrooms. Beyond bottles, we produce caps, tubs, tubes, and other disposable types of items.”

About the Author(s)

You May Also Like