The plastic packaging provider discloses sustainable innovations in designs and polymers for beverage cups, caps, and closures.

It usually takes a big company to make a big difference for improved sustainability.

Consider the developments of Berry Global, a Fortune 500 global manufacturer and marketer of plastic packaging products headquartered in Evansville, IN, with more than 48,000 employees working at 290 facilities worldwide.

On-trend with numerous packaging companies, Berry is going all out in making the plastic caps, closures, and cups it manufactures as sustainable as possible.

Following a brief, big-picture look at the company’s achievements, company managers share details about several packaging innovations.

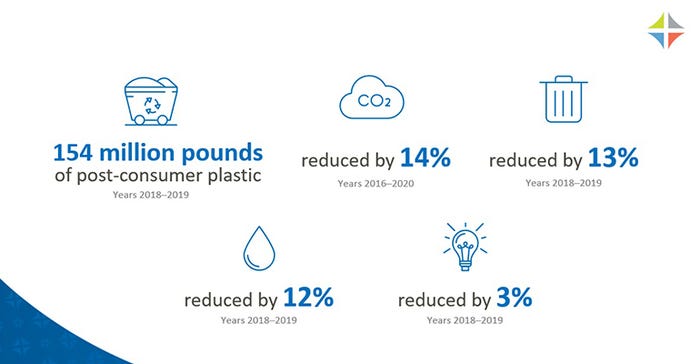

In a recent presentation, Brian Hunt, Berry Global’s EVP & general manager, closures, bottles, and specialties, summarized the packaging supplier’s major milestones and goals in this graphic:

Berry's sustainable journey is not without challenges that include securing reliable sources of high-quality post-consumer recycle (PCR) content.

“Currently, the number of approved streams for food contact mechanically recycled resins is limited,” acknowledges Diane Marret, Berry Global, sustainability director of consumer packaging, North America. “We continue to work with our suppliers to understand the limitations of use and incorporate PCR where feasible. There are new types of recycled resins coming online in the future to help meet the increasing demand for recycled content.”

This slideshow gallery show the ways Berry is making sustainable progress, starting with the Instagram-worthy Versalite cup.

About the Author(s)

You May Also Like