The label release liner market continues to increase at around 4% per year, with medical and industrial usage growing at a much faster rate, according to AWA Alexander Watson Associates (Amsterdam).

November 20, 2017

The annual industry update on release liner for pressure-sensitive (PS) labels was presented by AWA Alexander Watson Associates (Amsterdam) this year in Brussels. AWA President and CEO Corey Reardon opened the conference with an overview of the world’s label release liner market at the event co-located with Labelexpo Europe.

A release liner is a paper or plastic-based film sheet typically applied during the manufacturing process to prevent a sticky surface (label) from prematurely adhering. It is coated on one or both sides with a release agent, which allows a “release effect” against any type of sticky material.

“Pressure-sensitive labels still claim a 40% share of the total label market, and label release liner—constituting a 49% share of global release liner usage—continues to grow at around 4% per year,” said Reardon. “Liner usage for tapes, medical and industrial applications, however, are growing much faster.”

Reardon emphasized that PS labels remain a better option for the growing base of intelligent label technologies than other systems and, conversely, also highlighted some challenges, including the growing interest in linerless labeling and direct-to-container digital print. He also addressed recycling and sustainability concerns.

Isidore Leiser, CEO of Stratus Packaging in Luxembourg, provided some insights on the benefits of release liner for a converter and label user. PS labels can be applied at speeds reaching 22,000 labels per hour—much faster than in-mold or sleeve labels—and some converters are even applying liner on non-adhesive products to increase application speeds. While the available choices enable converters to be flexible in label production and quality, “most of our customers only look at cost advantages,” Leiser commented, adding that end users are not really interested in the relatively minor problem of coping with spent liner in an environmentally friendly way, since there are no cost advantages. Liner-based label production today represents a much smaller percentage of Stratus Packaging’s business than it did 35 years ago, “but it still offers real added value as part of the solution for some applications.”

|

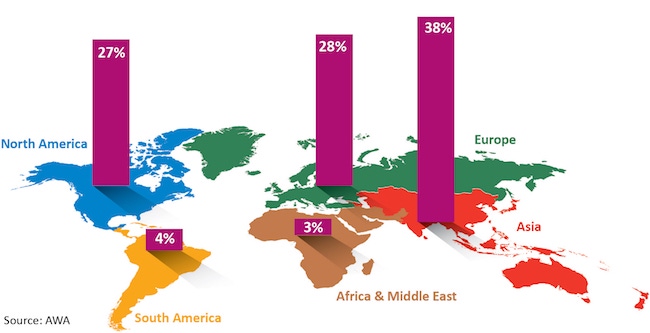

The global release liner market by region in 2016. |

Dow Corning’s TS&D Specialist Alexander Knott discussed silicone trends in release liner for PS labels. Today’s prime market drivers—sustainability, innovation driven by cost control and new applications that require release coatings—are pushing the industry in a number of directions. These include the need for flat release liner profiles for faster converting and labeling speeds; reduced platinum dependency; material downgauging; and the use of thinner/less-refined papers as a release base. Film liners are growing as a result of clear-on-clear labels and the use of heat-sensitive substrates; the adoption of digital label printing; and, in parallel, major increases in the use of liners for food-bakery applications in Europe.

In a session devoted to release label liner sustainability and recycling, Warren Lloyd, Avery Dennison’s Global Procurement Director for Materials, stated, “We pioneered the label industry, and hope to continue to do so.” The company has a strong interest in the environmental arena, which it is actively pursuing in the form of a number of sustainability goals that span both product and business functions, market outreach and a program of ongoing activities involving the wider supply chain.

Avery Dennison recently commissioned a research study from AWA Alexander Watson Associates dedicated to current release liner and matrix waste recycling/re-use practices around the world. The research provides a detailed picture of the available choices of disposal/recycling solutions in different countries and regions, from landfill to incineration for (or without) energy recovery to second-life recycling, noted AWA’s report on the conference.

The Polyolefin Circular Economy Platform (PCEP), founded by three plastics industry associations—EuPC, Plastics Europe and Plastics Recyclers Europe—had the opportunity to respond to environmental issues. Herman van Roost, Chairman of the Communications Group, detailed the group’s joint industry value chain initiative. With a to-do list featuring increasing recycling of polyolefin-based packaging and the use of polyolefin recyclates as raw material to ensure the long-term sustainability of such products, the PCEP is combining “a unique set of competencies: Polymer science, recycling and plastic conversion,” said van Roost.

Van Roost underscored the key strategic goals of the initiative, including enhanced collection and sorting of packaging waste, which represents a major source of polyolefin recyclate, and introduced the current working groups, which span topics such as innovation for increased recycling of flexible packaging; end-use markets for polyolefin recyclates; and technology innovations to improve mechanical recycling and conversion, noted the AWA conference report.

Reardon concluded the conference noting, “One day, when their other waste problems are solved, release liner will become an issue for brand owners. The topic of sustainability and recycling is, I believe, going to be one of the finite issues over the next 10 years, and when you’re talking about recycling in the label segment, you’re not just talking about one-liner substrate!”

About the Author(s)

You May Also Like