Solutions to technical challenges in making laminated flexible packaging recyclable are possible — here’s a detailed example of a vendor collaboration in India.

June 10, 2020

Packaging regulations and restrictions are a proven motivator for change worldwide. It’s also mobilizing the plastics industry to accelerate research and development for sustainable packaging improvements and options.

In India, following the announcement of the Plastic Waste Management Rules (PWMR) by the Indian government that includes phasing out the manufacture of non-recyclable or non-energy recoverable or multilayer plastics (MLPs), ExxonMobil took up the challenge of replacing MLPs with recyclable full polyethylene (PE) laminated solutions. MLPs are any packaging structure with at least one layer of plastic as the main ingredient combined with one or more layer of other materials such as paper, paper board, polymeric materials, metalized layers, or aluminum foil.

ExxonMobil is substituting MLPs with full PE laminated solutions for nonbarrier-based packaging applications such as for wheat flour, detergent, and salt. The conventional laminate structure for such applications is generally PET/PE with PET as the top layer/substrate and PE as the sealing layer. When changing from a PET/PE laminate to a full PE-laminated solution, customers generally face issues in the following areas:

▪ Significant drop in packing speed;

▪ Unsatisfactory optics;

▪ Change in sealing requirements;

▪ Significant changes in machinery, resulting in high costs.

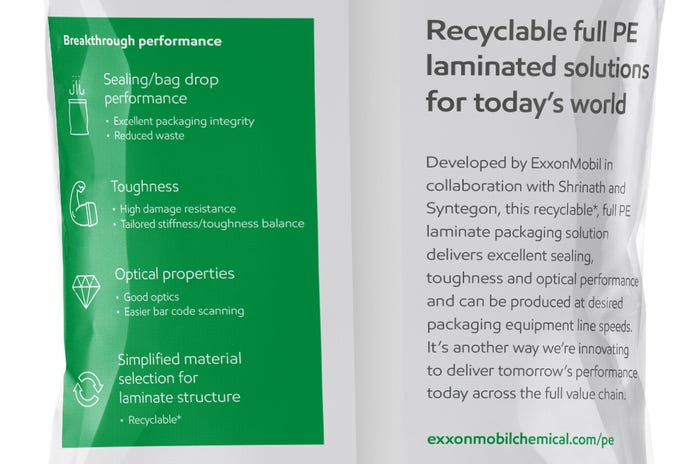

The challenge was to develop a technical solution for full PE laminates which could run at the desired printing and packaging equipment line speeds, while delivering excellent optical properties. ExxonMobil developed multiple full PE laminated formulations that were specifically designed to address the above issues, teaming up with the Shrinath Group, a leading film converter in India with excellent infrastructure and production capacity in blown film, printing, and lamination.

Using ExxonMobil's performance PE polymers ― including ExceedTM XP 8784, ExceedTM 2012, EnableTM 4009, and ExceedTM 1327 ― as well as ExxonMobil HDPE HTA 108, solutions for the PE substrate/top film and the PE sealant film were successfully produced at Shrinath on its Reifenhauser 3 layer blown film line. Substrates were then converted into laminates after printing on rotogravure (BOBST Rotomec) as well as Central Impression (BOBST F&K) flexographic printing machines. Lamination was carried out on Nord Meccanica Simplex machines.

For the form-fill-seal (FFS) packaging trial, ExxonMobil collaborated with Syntegon Technology India Private Limited (formerly known as Bosch Packaging Technology), a leading supplier of packaging machines. The trials took place at the plant in Goa, with participation by ExxonMobil and Shrinath. Trials were conducted on an SVZ 1803AR high-speed intermittent-motion vertical FFS machine with jaw draw-off technology and servo cross sealing system. The compact, versatile, and operator-friendly bag maker consistently produces accurate bags and quality seals with robust design suitable for abrasive and corrosive products.

Line speeds of a maximum 65 bags/min for 500g and 1kg packs could be easily achieved without any operational challenges. Subsequently, the packs passed drop and leak tests to confirm packaging integrity.

For further technical details and recommendations, visit the website.

About the Author(s)

You May Also Like