The NexPET system will benefit established companies producing niche brands or smaller-run SKUs as well as emerging producers seeking a fast, low-risk entry into markets, said Husky.

November 6, 2020

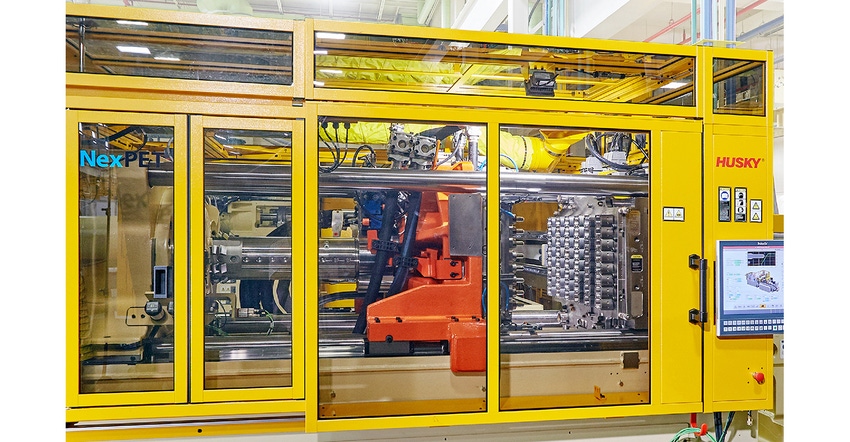

Husky Injection Molding Systems’ new NexPET system is described by the company as a game-changing mid-volume PET preform molding solution. It is designed to help producers introduce multiple new applications into the market quickly and cost effectively.

The preform system benefits both established companies producing niche brands or smaller-run SKUs as well as emerging producers seeking a fast, low-risk entry into markets, said Husky. It also allows manufacturers to respond nimbly to shifting market trends, such as greater consumer demand for personalized products. COVID-19 has amplified this trend globally, according to Robert Domodossola, President, Rigid Packaging. The pandemic has forced many producers to “rapidly adapt operations to scale up new applications like hand sanitizer, disinfectant, and other health, personal care, or cleaning related products,” said Domodossola.

The NexPET system can run up to a 48-cavity mold and is equipped with a number of productivity-enhancing features. In particular, Husky cites the following:

Faster mold changeovers;

different screw diameters to maximize production output flexibility;

a Reflex PET clamp to distribute the right amount of force and maximize mold life;

rotating end-of-arm tooling with up to three cooling positions to ensure preforms are ejected at ideal temperatures;

intuitive, easy-to-use controls;

adaptive system that automatically adjusts oil pressure to suit applications while conserving energy;

capability to run recycled PET pellets and varying quantities of flakes.

About the Author(s)

You May Also Like