Sponsored By

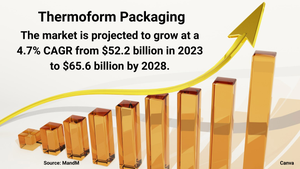

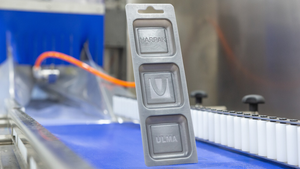

Packaging

thumbnail

Sustainability

What Sustainable Solutions Make Sense for Plastics?What Sustainable Solutions Make Sense for Plastics?

The tension between engineering and marketing is never more apparent than in sustainable packaging decisions.

Sign up for the PlasticsToday NewsFeed newsletter.