While demand for BOPP film continues to grow “respectably,” it is not advancing sufficiently to absorb capacity increases without causing a margin fight, according to a study from Applied Market Information (Bristol, UK).

June 12, 2018

In the space of two years, the bi-axially oriented polypropylene (BOPP) film industry has moved from a scenario of modest capacity growth and improving margins to one where it seems everyone is struggling to make money thanks to another frenzy of investment in high-capacity BOPP film lines around the world. That’s according to analysis from Applied Market Information (AMI; Bristol, UK). While demand for BOPP film continues to grow “respectably,” it is not advancing sufficiently to absorb capacity increases without causing a margin fight to either grow or maintain market share.

AMI noted that companies “with high debt and/or aging assets that cannot match the efficiency of modern equipment are particularly vulnerable. The new capacity increases are expected to drive rationalism of older capacity and/or merger and acquisition activity.” While profitability remains a challenge for the industry, the market continues to expand, with volumes growing by nearly 5% in 2017, the highest rate since 2012, driven by improving fundamentals in the global economy. This increased the global market to more than 8 million tons. The five-year compound annual growth rate for 2012 to 2017 was 4%, which has added just over 1.5 million tons of demand, said AMI.

|

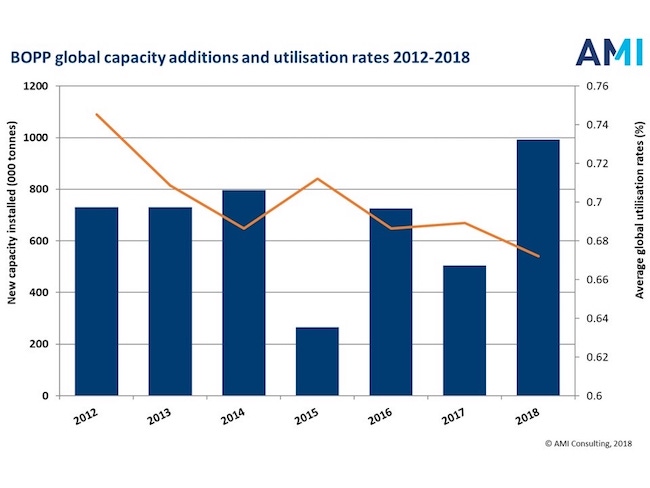

These strong underlying fundamentals are driving continuous investment in new capacity—more than 3 million tons of BOPP production were added globally between 2012 and 2017. Nearly two-thirds of that went to China, which accounts for nearly half of global capacity and demand. “For the first time its two leading producers, China Soft Packaging and Gettel Group, topped the world rankings in volume terms, although Taghleef and Jindal Films remain the leading players by turnover,” according to AMI Consulting.

This has led to utilization rates that are now below 70% on average. Utilization rates are also being challenged by growth in five-layer lines geared to more specialty grades and the drive by many companies to shift their product portfolio away from commodity coextrusion because of the poor margins. Specialty films tend to reduce line output because of shorter runs and more frequent changeovers. With at least 20 further lines expected in 2018 and 2019 adding nearly 900,000 tons of additional capacity, utilization rates are expected to remain below 70% after 2020, said AMI’s report.

The strength of the BOPP film industry stems from the high volumes used in primary packaging, particularly for food, which is not easy to cost-effectively replace. Growth in packaged food markets around the world will continue to be a key driver for future demand, underpinned by population growth, urbanization and rising incomes in developing markets.

AMI is forecasting the industry will continue to advance at around 4% a year to 2020, giving rise to a demand of more than 10 million tons.

About the Author(s)

You May Also Like