Elegant solution applies specialty ink to shrink-sleeve labels for seamless separation by existing magnetics during packaging recycling sortation.

December 20, 2021

Sometimes you hear about an idea that’s so simple and makes so much sense that you can’t believe it took this long to implement it. Even my esteemed SPRING colleague, Tom Brady, PhD, who has been around the recycling block a few times, calls this concept “brilliant”.

As many of you are aware, PET beverage containers are often wrapped with PET-G (or sometimes polyvinyl chloride aka PVC) shrink-sleeve labels. The problem is that the labels are contaminants in the recycling process. They have a density higher than water and can’t be separated from PET flakes during the sink-float separation step of the recycling process. Thus, they contaminate the recycled PET stream and reduce the quality of recycled PET (rPET).

California has gone so far as to consider PET-G to not be PET and does not allow it to carry a #1 RIC code. Thus, perfectly recyclable PET bottles that use shrink-sleeve labels never make it to MRFs, and usually end up in landfills.

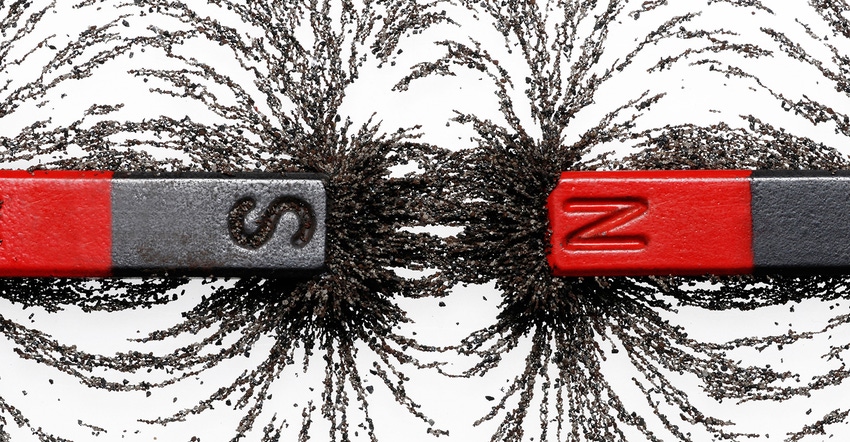

A startup company called Magnomer has developed a unique and rather elegant solution. Their process applies a magnetic ink to the shrink labels. The ink can be transparent or of various colors and is applied with standard label printing equipment.

When recovered bottles reach the processor, they are ground up as usual. As they leave the grinder for pelletizing, a magnet is used to attract and separate out the shrink label flakes.

Per a survey done by Magnomer in conjunction with the Association of Plastic Recyclers (APR), magnets are already in place to prevent metal contamination, so incremental investments, if required, will be minimal.

According to Ravish Majithia, founder and CEO of Magnomer, “what makes our system unique is its convenience. Recyclers get a cleaner PET stream without significant financial investments or changes in operating procedures. And consumers can simply drop the bottles in their recycling bins or return them for deposit repayments. Also, the need for consumers to look for and remember to remove perforated polyolefin labels prior to recycling is eliminated.”

Passes tests by American Fuji Seal.

Magnomer has successfully tested their system with label producer American Fuji Seal and a global beverage company in fully commercialized, scaled up labelling and bottling facilities. They are engaged with the APR for their Innovation Recognition program. The Recognition program entails commercial-scale testing at a minimum of two MRFs and two reclaimers. Magnomer expects to receive APR recognition in Q1 2022.

There’s another benefit to Magnomer’s technology: It has benefits for paper recycling streams as well. It could allow materials recovery facilities (MRFs) to cost effectively use magnets to separate out laminated films, such as chips bags. This would help remove plastic contamination from paper bales, where these flexible packages often end up today

I asked the director of a county solid waste management district in the Northeast for their thoughts regarding this approach and was told that, “if proven out in the ‘real world’, I think it would be a big help in that consumer confusion would be eliminated regarding whether or not they’re supposed to remove labels from PET bottles. One less rule makes consumer education easier. Removing foil laminated snack bags from fiber runs would be great, particularly in high volume MRFs.”

Robert (Bob) Lilienfeld has been involved in sustainable packaging for 25 years, working as a marketing executive, consultant, strategic planner, editor, writer, and communications expert. He’s President of Robert Lilienfeld Consulting, working with materials suppliers, converters, trade associations, retailers, and brand owners. He is Executive Director at SPRING, The Sustainable Packaging Research, Information, and Networking Group. You can also write him at [email protected] or visit his LinkedIn profile.

About the Author(s)

You May Also Like