Company to present several new products and live demos at NPE2018 with innovative design improvements for safer, high-volume flexible packaging and blown film production lines.

April 23, 2018

Pearl Technologies (Savannah, NY) will be showcasing several new packaging products accompanied with live demos in its booth at this year’s National Plastics Exposition. The new products are aimed at increasing converter line productivity, product quality and safety.

“We are showcasing several new products that create value for our customers addressing the need for continued productivity gains while improving worker safety,” said Laurent Cros, CEO of Pearl Technologies. “Our new units will be available for testing in the booth using customer-specific material for a first-hand demonstration that highlights ease-of-use and new safety features.”

EastPack 2018 held June 12-14 at the Jacob K. Javits Convention Center in New York City features the latest in manufacturing and automation, a dedicated 3D Printing Zone, hundreds of exhibitors and a jam-packed 3-day packaging conference. For more information, visit the EastPack website. |

New products include:

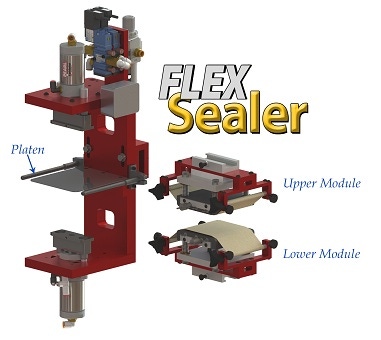

Double-sided Flex Sealer (above)

Pearl’s intermittent Flex Sealer is ideal for sealing poly bags or pouches in the bag making process. The Flex Sealer has conveniences similar to a Pearl Flex punching unit, including the ability to change sealing style, pattern, shape or size. Sealer modules can be swapped in seconds to change the pattern or for cleanup allowing converters to continue production during maintenance. Pearl’s Flex Sealer is great for gusset sealing applications, reinforced handle seals, angle seals, security seals, pre-sealing, heat crimping and more. Available in side rail or cross rail, carriages are optional. Flex Sealers can also be converted into Flex cutters.

Bubble guide digital control and readout

The bubble guide control unit features a simple touch screen control box that lets extruders remotely adjust the diameter of bubble guides. The system can also store recipes and can be purchased with a new bubble guide or retrofitted onto existing Pearl guides and cages.

Double-Center Pivot Punch (left)

Double-Center Pivot Punch (left)

Capitalizing on the success of Pearl’s patented pivot punch technology, the Double Center Pivot Punch unit allows users to punch holes very close to each other (1”) without needing multiple rails. The unit features the new center pivot allowing converters to benefit from the durability and quality of Pearl’s punches for continuous motion applications.

Lightning Multi-Punch Unit

Utilizing the lightning technology, widely used in wickets application, this complementary design offers the convenience of very fast changeovers, tool-less lateral adjustment, and the optional safety box, which prevents the exposure of the punch teeth during changeover.

Other featured products will include large diameter Ball and Die, UltraFlex HD, Flex 3, Lightning Wicket with Safety Enclosure and a full set of extrusion solutions and line enhancements.

About Pearl Technologies, Inc.

Pearl Technologies supplies precision converting products to the global flexible packaging and blown film industries. Pearl’s products are recognized for improving worker safety and driving greater throughput in the line delivering lower cost of ownership. Key products include a wide variety of punches, slitters and perforators, punching attachments for wicketing, handle holes, hanger holes, and venting attachments. Founded in 1985, the company ships products to customers in more than 35 countries worldwide. For more information visit pearltechinc.com.

About the Author(s)

You May Also Like