The expansion also supports compounders and processors that want to add Palsgaard’s Einar products to polymers directly rather than as part of a masterbatch formulation.

February 2, 2021

Citing growing demand for more natural ingredients and additives to meet sustainability goals, Palsgaard A/S has opened a new 10,000-tonne pellet line. The addition also expands production capacity for the Einar brand plant-based polymer additives at its facility in Juelsminde, Denmark.

“We are seeing fast-growing demand among consumers, brand owners, packaging designers, and plastics manufacturers for more natural materials to reduce fossil depletion and waste,” said Ulrik Aunskjaer, Global Industry Director, Non-Food Business Development, Polymer Additives. “Our expanded production capacity meets these requirements by boosting the availability of food-grade, plant-based surfactants and modifiers for polymer manufacturers and compounders.”

The expansion of the pellet line also addresses the needs of compounders and processors who may wish to add specific Einar products to polymers directly rather than as part of a more-complex masterbatch formulation. This applies in particular to the use of Einar antistatic additives for food and other packaging applications, where the availability of pelletized products enables a clean and straightforward process, added Palsgaard.

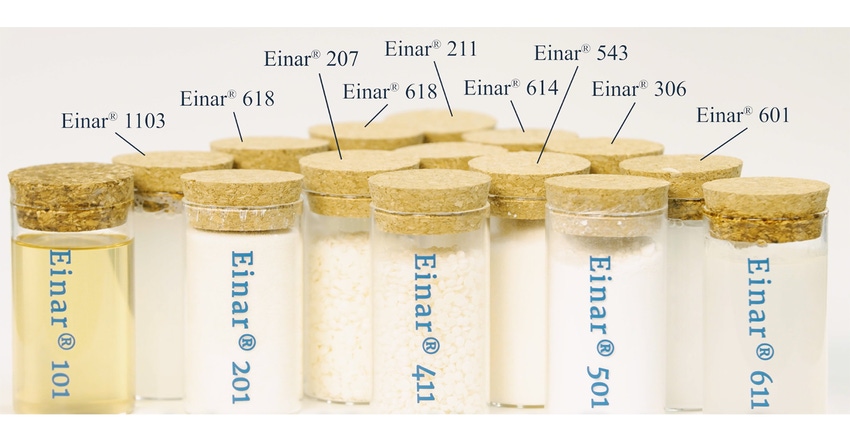

Palsgaard offers its Einar anti-fog and anti-static additives in several grades tailored to film, injection molding, foam, and coating processes for a range of different polymers, from polyolefins and PVC to PET and engineering plastics. Additionally, the Einar portfolio also includes slip additives, ageing modifiers, mold-release agents, and dispersing aids. All products have full FDA and EU food-contact approvals.

About the Author(s)

You May Also Like