A new report from the Flexible Packaging Association (Annapolis, MD) provides a holistic view of the sustainability benefits that flexible packaging offers.

April 17, 2018

Too often, plastics nay-sayers are quick in their efforts to rid the world of plastic based on some superficial reasoning such as plastics are non-recyclable, toxic, dangerous to sea life, you name it. They then cite the benefits of using alternative materials such as paperboard, metal or glass without going deeper into the supply and manufacturing chain.

|

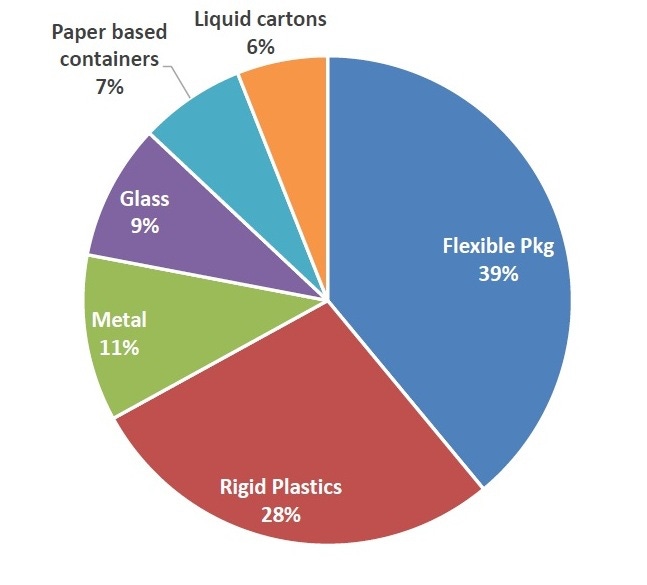

Global packaging overview by type in 2017. Chart courtesy Euromonitor/Flexible Packaging Association. |

The Flexible Packaging Association (FPA; Annapolis, MD) commissioned PTIS LLC to provide a holistic view of the sustainability benefits flexible packaging offers compared with other types of packaging. Many people—including product developers and designers and especially consumers—do not consider the science of plastics in light of all the benefits plastic materials offer, including a “light” manufacturing footprint and the value of the plastic at the end of the products’ useful life span.

The report notes that of the 3.506 billion units of packaging sold, 39% is flexible packaging, 28% is rigid, 11% is metal, 9% is glass, 7% is paper-based and 6% is liquid cartons. Flexible packaging represents approximately 19% of the $164 billion U.S. packaging industry by sales dollars.

It’s easy to see why flexible packaging has become the preferred packaging material, particularly in the food and beverage market: Portability, safety, product freshness and convenience, shelf stability and shelf-life extension, notes the executive summary of the report. Those benefits have driven demand for flexible packaging and resulted in a trend toward conversion from other package formats. Transportation issues also come into play, as the films used in creating flexible packaging are shipped flat or in rolls, which allows more material to be shipped per square foot of trailer space.

With the “convergence of more people and more packaging” it’s becoming increasingly critical that all parties involved understand the science behind the various packaging materials—from raw material to pellet to product—and the issues surrounding sustainability and end-of-life.

“It is important to remember that while sustainability is an important attribute to consider when selecting an appropriate package, it cannot be considered alone and must be thought of more holistically through the product and package lifecycle,” the report states.

Choosing a packaging material in isolation based solely on something like bio-degradability, for example, may ultimately be a bad choice, especially when you get down to the science of bio-degradability and what that term might—and might not—mean with respect to the requirements of the package, namely:

The supply and manufacturing chain of the package including energy use;

the unintended impacts of the packaging if it gets into the recycling stream; and

just how long a package would take to bio-degrade on the side of the road.

“Holistic Package Design (HPD) includes developing the many attributes and benefits previously described, while also building and incorporating sustainable package elements early in the process,” the report states. “The majority of the carbon footprint of a package is locked in at the package selection point.”

The FPA report rightly notes that sustainability must be viewed from a vantage of profitability, because all businesses exist for and by profitability. However, the report looks at what it calls the “triple bottom line”—people, profit and planet. The environmental impact requires evaluation from package concept through the entire supply and manufacturing chain, not just where the package will go at the end of its life. Yet, that’s often where much of the emphasis is placed, both at the brand-owner’s end and the consumer’s consideration when purchasing a packaged product.

In between package design and development there are other environmental impacts including the use of various resources such as water (paper requires a lot of water resources to manufacture, which should be a primary consideration when fast food restaurants determine that paper is better than plastic) and energy, not just at the manufacturing plant but at the agricultural level for bio-based packaging which includes planting, fertilizing, harvesting and shipping to the manufacturing plant to be made into plastic.

The FPA report notes that new initiatives to improve the sustainability profile of flexible packaging will need to continue to be addressed. These include:

Technologies to drive recycling and collection and sorting of flexible materials;

investigation of new materials including compostable or bio-based packages;

enhanced processing technologies that extend shelf life and freshness such as vacuum packing, modified atmosphere packaging, and high pressure processing;

and increased consumer participation that includes making it easier for consumers to process difficult-to-recycle packaging such as polyethylene (PE) wraps that can be recycled with grocery store bags using in-store PE recycling bins.

Providing instruction labels on packaging might help, as noted in the report: “Recycle if clean and dry.” That requires some proactive work on the part of the consumer such as rinsing and drying the package before putting it in the recycle bin.

At the end of the day, the FPA report makes a salient point: “Like all packaging, if not properly disposed of by consumers, flexible packaging can end up as litter or marine debris, where it is very difficult to collect. Consumer education about proper disposal of packaging waste is needed in order to drive consumer behavior.”

And that is the biggest challenge of all!

The 191-page report, A Holistic View of the Role of Flexible Packaging in a Sustainable World, can be obtained at www.flexpack.org.

About the Author(s)

You May Also Like