As the coronavirus crisis casts polystyrene and PS products in a more favorable light, chemical recycling could change the long-term sustainable equation for the polymer.

March 17, 2020

Last month, I wrote about one way in which a converter (Kwik Lok) was using an evolutionary approach to enhancing the sustainability of its polystyrene (PS)-based closures. For this month, I decided to go upstream and ask the same question of one of the major PS producers, INEOS Styrolution.

For reference, Ineos Styrolution is a €5 billion/$5.5 billion global styrenics supplier, headquartered in Frankfurt, Germany, with US headquarters in Aurora, IL. It provides styrenics products for applications in everyday products across a broad range of industries including food service packaging, household, automotive, electronics, and leisure.

Ineos Styrolution also interested me because of its recently announced partnership with Agilyx to build a polystyrene chemical recycling plant in Illinois. If you follow my LinkedIn postings, you’ll know that I am actively researching the potential of chemical recycling and consider it to be an evolving companion strategy to mechanical recycling.

I’m sure you’re also aware that many NGOs, legislative bodies, and regulatory organizations are calling for significant increases in recycled content and use of recyclable materials. With their public announcements regarding these goals, many global CPGs are expecting to significantly increase their use of recycled plastics over the next five years. Thus, any strategy that can efficiently and effectively add high quality, recycled, packaging-oriented content to the mix is sorely welcome.

To learn more, I interviewed Ricardo Cuetos, Vice President Americas for Ineos Styrolution. My first question related to the advantages of chemical versus mechanical recycling. According to Cuetos, “There are two important benefits to chemical recycling. First, it’s a truly closed loop. Unlike traditional mechanical recycling, the process does not degrade the quality of material and therefore does not require supplementation from virgin material after many recycling cycles. Second, chemical recycling can handle mild contamination from food residue, dirt, etc. With traditional mechanical recycling, these contaminants need to be washed and separated, thus limiting the amount of material that is recycled and preventing a closed loop system.”

His second point can be particularly beneficial for foodservice or agricultural packaging, where food or dirt can, and do, contaminate collection streams, preventing the material from being recycled. With chemical recycling, these disadvantages are removed, allowing for more polystyrene items to be added to consumer, restaurant, retail, and industrial recycling streams.

PS: sustainability potential.

I mentioned that I thought the current coronavirus situation has put the overall sustainability potential of polystyrene, along with virtually all single-use plastics and plastics applications, into new focus. For example, the sanitary nature of single use items such as cups, containers and utensils used in foodservice provides a measure of hygiene and social safety that we’ve unfortunately come to take for granted.

I asked Cuetos if this was enough to qualify polystyrene as a sustainable resin. He answered that, “We must also think about the economic and environmental benefits. Economically, polystyrene provides a great deal of price competitiveness. Environmentally, this new capability to constantly produce virgin quality material from recycling streams, even those with moderate levels of contamination, is also a significant sustainability enhancement.”

I had one more question for Cuetos, regarding the fact that polystyrene is not currently considered to be widely recyclable. He commented that, “Our large investment in PS chemical recycling opens the doors for the creation of significant increased demand for recycled resin from both businesses and communities. We’re counting on this new interest to help us achieve recycling volumes and rates that will allow us to be included in the short list of polymers that are considered to be widely recyclable, and just as importantly, widely recycled.”

Welcome to the Sustainable Packaging Evolution, Ricardo.

Attention readers: I’d love to hear your evolutionary war story, too!

Robert (Bob) Lilienfeld has been involved in sustainable packaging for 25 years, working as a marketing executive, consultant, strategic planner, editor, writer, and communications expert. He’s President of Robert Lilienfeld Consulting, working with materials suppliers, converters, trade associations, retailers, and brand owners. Reach him at [email protected].

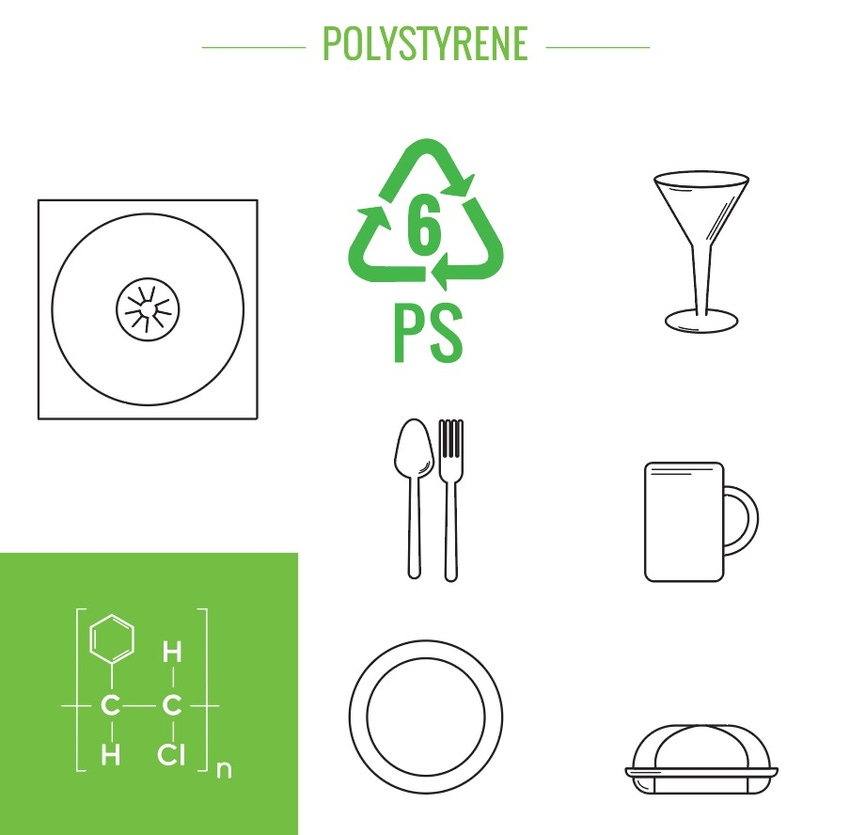

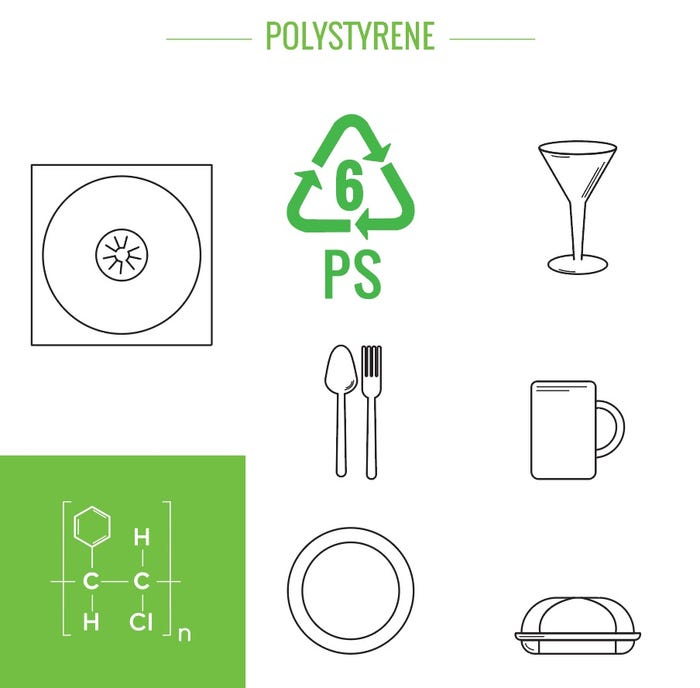

Image: Анна Комелева/Adobe Stock

About the Author(s)

You May Also Like