It wasn't but a decade ago that plastic pallets were just beginning to come into wide-spread use, and while wood pallets are the most commonly used type, plastic pallets will register more impressive inroads into the pallet market over the next few years. Plastic pallets in particular, have seen the strong advances historically in percentage terms, according to the Freedonia Group, a Cleveland-based market research firm, and they will continue to record above average stock and demand increases.

December 23, 2013

It wasn't but a decade ago that plastic pallets were just beginning to come into wide-spread use, and while wood pallets are the most commonly used type, plastic pallets will register more impressive inroads into the pallet market over the next few years. Plastic pallets in particular, have seen the strong advances historically in percentage terms, according to the Freedonia Group, a Cleveland-based market research firm, and they will continue to record above average stock and demand increases. Currently there are 1.1 billion total pallet units in the U.S., with a projected 2.4% annual growth rate to 2.6 billion units in 2017.

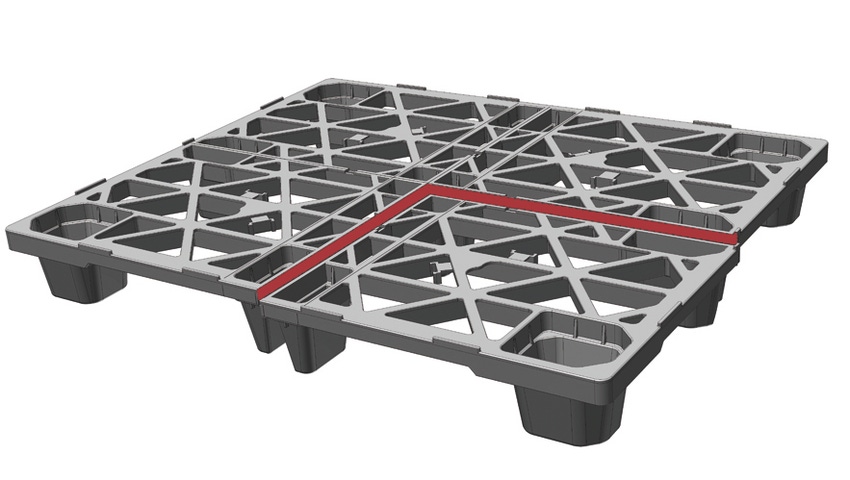

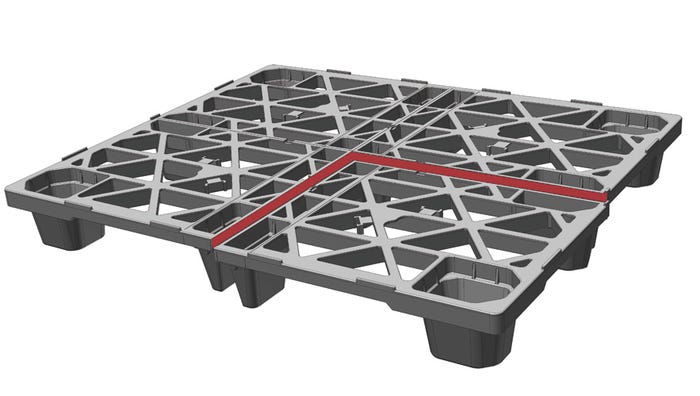

Among plastic pallets benefits are their strength, their resistance to chemicals, insects and fire. There are numerous plastic pallet and container manufacturers, introducing a variety of strong, lightweight pallets to reduce shipping costs and improve fuel efficiency in transport. Recently, CABKA, a manufacturer of plastic pallets, containers and bins, is now  offering a lightweight, nestable half pallet, the CPP 200. With dimensions of 32 x 24 x 5.1 inches and a weight of only 8.5 lbs., the pallet is very easy to handle at the point of sale and safer as well, according to information supplied by the company.

offering a lightweight, nestable half pallet, the CPP 200. With dimensions of 32 x 24 x 5.1 inches and a weight of only 8.5 lbs., the pallet is very easy to handle at the point of sale and safer as well, according to information supplied by the company.

The new size of the CPP 200 "perfectly cubes out" many common-sized displays and RPCs used in various applications, including the retail level. Its rounded corners, smooth surfaces and low weight offer decisive advantages when empty pallets much be moved and stacked, according to St. Louis, MO-based CABKA.

The new CPP 200's special design allows it to carry dynamic loads of up to 2200 lbs., with a nesting height of only 2.2 inches. This permits dense stacking of empty pallets, which considerably reduces freight costs, reduces storage costs and protects the environment. The CPP 200 is made of ACM recycled material, offering a cost effective alternative wooden pallets, the company said. It is also available in special recycled PE material for closed loop shipments were a much lower cost per trip is applicable.

Using recycled plastics in pallet molding is becoming popular as a way to improve sustainability for companies looking to reduce their carbon footprint. Greystone Logistics Inc., a "green" manufacturing and leasing company that reprocesses and sells recycled plastic and designs, manufactures, sells and leases high-quality 100% recycled plastic pallets. With headquarters in Tulsa, OK, and a manufacturing facility in Bettendorf, IA, Greystone's injection molded pallets are made from a proprietary blend of recycled plastic resins, including post consumer products such as car bumpers.

This month, Greystone announced the company manufactured and shipped recycled plastics pallets to various sites in the Anheuser Busch system as part of a pallet test and production evaluation. "Greystone is pleased that Anheuser Busch has purchased pallets to supplement their existing plastic pallet pool," stated Warren Kruger, CEO. "These pallets will be evaluated during a testing phase to ensure utilization characteristics that conform to the manufacturing and distribution processes of Anheuser Busch. The Greystone pallet design uses 100% recycled plastic, offers a long life cycle, can be recycled, has substantial racking strength and has the best coefficient of friction in the plastic pallet industry."

Intelligent Global Pooling Systems (iGPS), operator of the world's first pallet rental service featuring lightweight, 100% recyclable plastic pallets with embedded radio frequency identification (RFID) technology, recently announced that it finalized its sale to iGPS Logistics LLC, a joint venture formed by Balmoral Funds, One Equity Partners, certain of their affiliates, and Jeff and Robert Liebesman.

The Orlando, FL-based company created what it calls "the most advanced and cost-efficient platform-based shipping solutions" whose lightweight recyclable plastic pallets and integrated technologies yield "game-changing savings for both manufacturers/growers and retailers." iGPS embedded RFID technology helps companies track the pallets through the transportation system, and has even helped law enforcement track and locate pallet thieves who in some cases, were operating plastic recycling operations with the stolen pallets.

"We are extremely excited to have completed this transaction," said Jeff Liebesman, the new CFO of iGPS Logistics. "Our new capital structure, combined with the pooling experience brought by the existing management team, Robert and myself, will enable us to enhance our current operations and expand our product offerings in the years ahead."

"iGPS has been a true innovator with an outstanding value proposition," Liebesman added. "The company is now well positioned to continue to pursue its mission of adding real value to our customers and to all segments of the supply chain."

About the Author(s)

You May Also Like