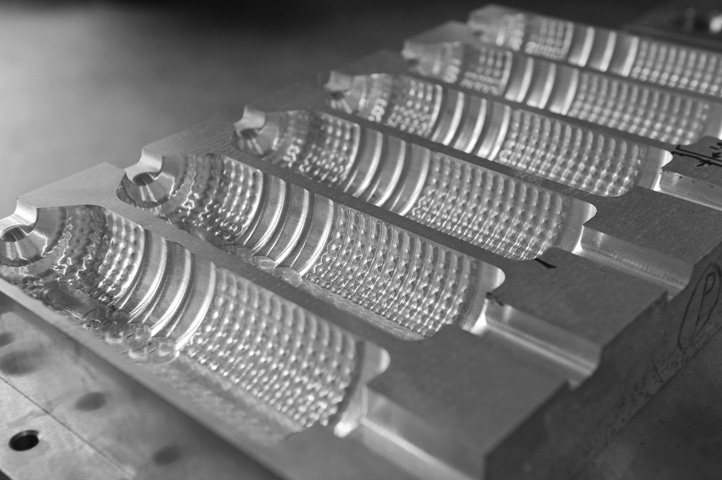

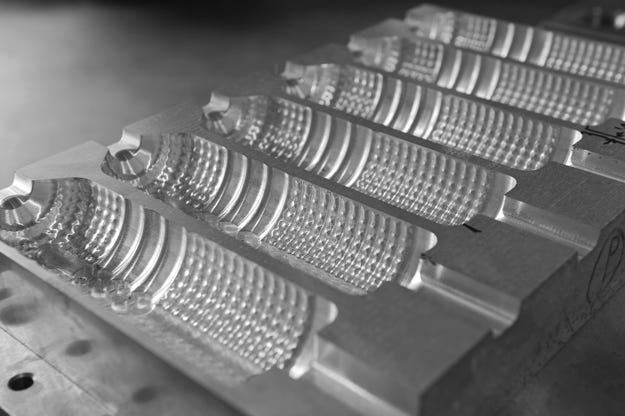

Demand for aluminum molds has consistently increased over the past decade, and Harry Raimondi, Technical Services Manager for Bales Metal Surface Solutions, says the trend shows no sign of reversing. Bales Metal Surface Solutions (Downers Grove, IL) provides metal coatings for a variety of fabricated metal components, but its big business is mold coating and plating.

May 12, 2015

Demand for aluminum molds has consistently increased over the past decade, and Harry Raimondi, Technical Services Manager for Bales Metal Surface Solutions, says the trend shows no sign of reversing. Bales Metal Surface Solutions (Downers Grove, IL) provides metal coatings for a variety of fabricated metal components, but its big business is mold coating and plating.

"There's more demand for aluminum production molds, and it's becoming a bigger part of our business," Raimondi told PlasticsToday, noting several reasons for this. "It started out as being the metal of choice for prototype tooling when someone only needed 2,000 parts. Then companies started running more and more parts, and found out that the aluminum molds could actually hold up longer than predicted."

However, the life of an aluminum mold can be extended even further if the mold is plated with electroless nickel. "Plastic is abrasive and the tool wears, causing flash conditions on the parts," Raimondi said. "With electroless nickel plating you can take an aluminum mold from 18 RC (Rockwell hardness) to 50 RC, so it's a very cost-effective way to extend the life of aluminum tooling."

Because aluminum machines much faster, companies can achieve faster speed to market or to get engineering samples. "Shorter lead times have become pretty critical to companies, so we're trying reduce the lead times on molds. We've been contacted by some major automotive suppliers about aluminum tooling because certain parts can be done in aluminum molds."

Another reason for the increased demand for aluminum production tooling is that aluminum suppliers are coming out with better aluminum, and the quality is allowing it to be machined more easily. "Some grades are very gummy and tougher to machine and polish, but there are some grades out now that machine easy, which saves time, and have very good polishability, almost lens quality," Raimondi added.

Another benefit of an aluminum mold is its thermal conductivity, which means faster cycle times. For OEMs who need higher volumes, plating or coating offers increased protection for the mold, as well. Not only can the outer surfaces be plated with either electroless nickel or chrome, but the water lines can be plated, as well. Electroless nickel-based materials offer very even coating, and the need for mold spray can be reduced if using Bales' nickel and Teflon (called Niklon) coating.

Not only does the plating or hard coating give the tool longevity, it helps reduce mold maintenance. "Once it's coated with electroless nickel, you can clean it easier, and keep it clean with mineral spirits or alcohol," said Raimondi.

It is possible to re-plate a mold by removing the old coating for repairs or welding. Some areas of a mold, such as the gate area, which tends to be the first area to exhibit wear, the nickel plating becomes a wear indicator. "Then you know you need to re-plate the mold," Raimondi said. "When you only have a couple tenths of initial deposit, preventive maintenance becomes important, a time to strip and re-plate."

Bales offers a number of plating and coating types. In addition to Niklon, they offer a nickel boron coating called Nibore and a diamond nickel plating with diamond particles in it. "This is good if you need a harder coating for more abrasive plastic materials or more lubricity," said Raimondi. "If you have a release issue with the geometry of the part, nickel boron or Nibore, would be the way to go."

Because Bales performs both polishing and plating operations, Raimondi explained that in some cases if the base aluminum doesn't have the quality required, they plate and then post-polish the plating to improve upon the finish. "Nickel won't fill in little pin holes or pits in the base material-the nickel will enhance those imperfections," he said. "The key is in knowing the quality of the molded part the mold will produce, then you'll know what type of plating and post-polishing is required."

The plating is not done in layers but is a continual process. "We have a way to know how much plating is being deposited—we call it precision plating, because we can control the deposition much better than our competition because we're dealing with precision parts," Raimondi said.

Bales offers polishing and plating as a total package, which is an advantage for customers. "With some companies you sometimes need two houses--one only does plating, not the polishing," said Raimondi. "If you want an A-1 or A-2 diamond finish you have to have post polishing performed after the plating."

Raimondi concluded that, "aluminum will only grow in demand."

About the Author(s)

You May Also Like