Photonic crystal cavities made from poly(methyl methacrylate) (PMMA), which swells when it comes into contact with gases, have enabled researchers at MIT's Quantum Photonics Laboratory to develop extremely sensitive and compact optical sensors that can detect minute amounts of target molecules. The PMMA can be treated to interact with various target chemicals, making the sensors suitable for a range of applications from antibody detection in medical applications to the sensing of toxic gases for homeland security purposes.

June 19, 2014

Photonic crystal cavities made from poly(methyl methacrylate) (PMMA), which swells when it comes into contact with gases, have enabled researchers at MIT's Quantum Photonics Laboratory to develop extremely sensitive and compact optical sensors that can detect minute amounts of target molecules. The PMMA can be treated to interact with various target chemicals, making the sensors suitable for a range of applications from antibody detection in medical applications to the sensing of toxic gases for homeland security purposes. The research is described in the journal Applied Physics Letters.

The PMMA is infused with fluorescent dye, which emits selectively at the resonant wavelength of the cavity through a process called the Purcell effect. At this resonance, a specific color of light reflects back and forth a few thousand times before eventually leaking out. A spectral filter detects this small color shift, which can occur at even subnanometer-level swelling of the cavity, and in turn reveals the gas concentration.

|

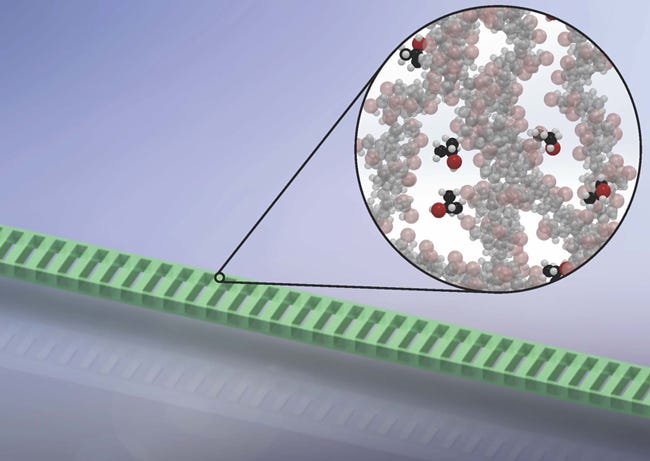

The inset shows the target gas molecules (darker) interacting with the polymer material (lighter). The interaction causes the nanocavity to swell, resulting in a shift of its resonance. Image courtesy H. Clevenson/MIT. |

"These polymers are often used as coatings on other materials, so they're abundant and safe to handle," says Hannah Clevenson, a PhD student in the electrical engineering and computer science department at MIT, who led the experimental effort in the lab of principal investigator Dirk Englund. "Because of their deformation in response to biochemical substances, cavity sensors made entirely of this polymer lead to a sensor with faster response and much higher sensitivity."

The 400-nm-thick PMMA films are patterned with structures that are 8 to 10 micrometers long by 600 nanometers wide and suspended in air. In one experiment, the films were embedded on tissue paper, which allowed 80% of the sensors to be suspended over the air gaps in the paper. Surrounding the PMMA film with air is important, Clevenson says, both because it allows the device to swell when exposed to the target gas, and because the optical properties of air allow the device to be designed to trap light traveling in the polymer film.

The team found that these sensors are easily reusable since the polymer shrinks back to its original length once the targeted gas has been removed.

The current experimental sensitivity of the devices is 10 parts per million, but the team predicts that with further refinement, they could detect gases with part-per-billion concentration levels.

About the Author(s)

You May Also Like