Oil pans fitted in the 12.8-liter Euro 6 engines for the Mercedes Actros from Daimler boast impressive dimensions of up to 120 cm long, 40 cm wide and 35 cm deep. To date, they are the largest engine oil pans for trucks to be made of polyamide (PA) 6 and 66.

October 21, 2011

Oil pans fitted in the 12.8-liter Euro 6 engines for the Mercedes Actros from Daimler boast impressive dimensions of up to 120 cm long, 40 cm wide and 35 cm deep. To date, they are the largest engine oil pans for trucks to be made of polyamide (PA) 6 and 66.

|

Oil pans molded from 6 and 66 PA grades stand up to the on-road challenges presented by truck transport. |

They are manufactured by BBP Kunststoffwerk Marbach Baier GmbH (Marbach, Germany) using Durethan from Lanxess (Leverkusen, Germany). "We used a series of calculations and simulations to confirm the feasibility of the oil pans in advance, thus helping to ensure that the pans could be designed on the computer properly and cost-effectively over a relatively short development period," explains Frank Krause, a Lanxess expert for oil-carrying engine parts made of plastic.

In this particular application, polyamide offers an alternative to aluminum, sheet steel and sheet molding compounds (SMC). It produces far lighter components than die-cast aluminum, for example. What's more, polyamide components made using injection molding processes are ready for use straight away. In contrast, die-cast and SMC parts often have to undergo laborious and costly additional processing in order to remove burring, for example.

One variant of the oil pan for the 12.8-liter engine is made of the heat-stabilized PA 66 Durethan AKV 35 H2.0 filled with 35% glass fiber. Another variant is manufactured using the corresponding polyamide 6 grade Durethan BKV 35 EF H2.0. "In the course of the joint development work, it transpired that PA 6 too is able to cope with the high demands made on these large components that are exposed to a range of temperatures and pressures," says Krause. Durethan BKV 35 EF H2.0 offers an additional advantage, as its glass fibers are less prominent on the surface. This ensures a high degree of tightness in the groove areas and improved removal from the mold.

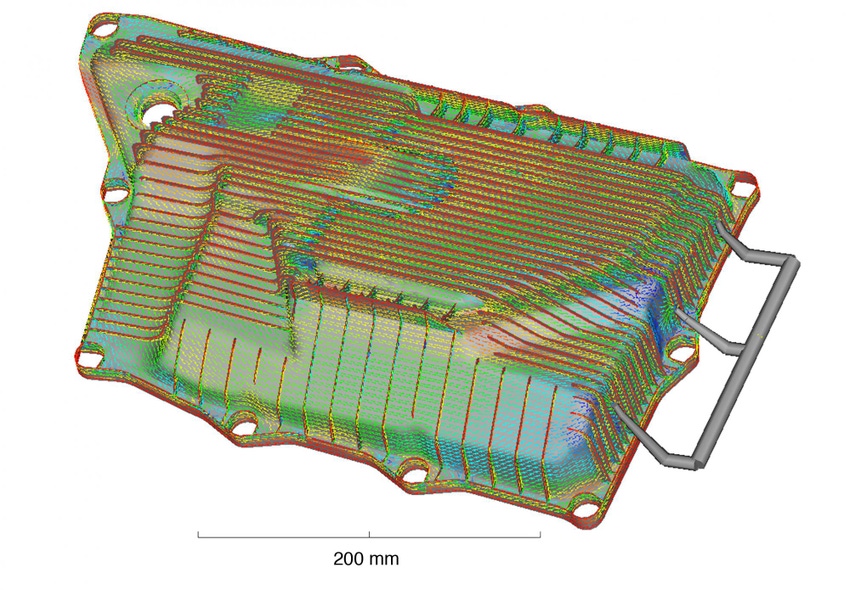

During the development of the oil pans, Lanxess provided its partners with comprehensive support in the form of calculations and simulations. This included structural optimization to improve the acoustic behavior of the pans, and a simulation exercise to examine resistance to stone chippings and deformation on exposure to sealing force. Simulations were also carried out for the filling of the injection molds and the distortion behavior of the oil pans. "These calculations helped us to ensure the molds were filled evenly, particularly in the flange area, thus minimizing distortion," says Krause.

Other investigations examined how the oil pans would behave if the entire engine block, including the transmission, was removed and set down for maintenance work or repairs. In this instance, the pans would have to bear a weight of around 1.6 metric tons. Integral simulation was used to provide detailed analysis of the directionality of the thermal expansion around the flanges resulting from the varying fiber orientation in the component. "We used this to derive measures to ensure the tightness of the flange under all the potential temperatures and pressures," says Krause.

The simulations and calculations conducted by Lanxess as part of the development of the two engine oil pans are all part of HiAnt. "This brand incorporates all the services received by our customers worldwide as part of the development of innovative system solutions. HiAnt stands for our know-how in the development of products, applications, processes and technology. This expertise is what really sets us apart from many of our competitors," claims Krause.-[email protected]

About the Author(s)

You May Also Like