A novel polymer-bound antioxidant for polyurethane (PU) reportedly addresses more-stringent environmental, health and safety requirements while delivering outstanding thermal stabilization performance at low loadings.

June 8, 2015

A novel polymer-bound antioxidant for polyurethane (PU) reportedly addresses more-stringent environmental, health and safety requirements while delivering outstanding thermal stabilization performance at low loadings. Milliguard AOX-1 from Milliken & Company is said to offer a unique solution for compliance with tougher vehicle indoor air quality standards - such as China's new passenger car air quality assessment guidelines and similar emerging standards in other regions - by contributing negligible volatile organic compound (VOC) and outgassing condensation (FOG) content in emissions testing.

|

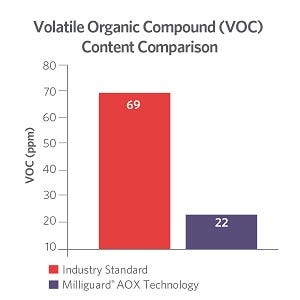

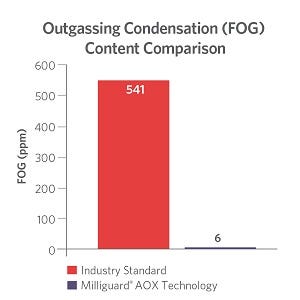

VOC emissions and outgassing condensation are dramatically reduced with new polymer-bound antioxidant. |

|

Milliguard AOX-1 antioxidant also offers unparalleled efficiency in stabilizing free radicals that can degrade polyurethane (PU) foam, and is highly synergistic with other antioxidant classes according to the supplier. It provides polyol producers and foam manufacturers with a powerful tool for interior vehicle components such as seats, door trim, carpet, instrument panels, headliners and consoles.

"Our patented Milliguard AOX-1 antioxidant can play an important role in helping passengers breathe more easily when traveling in a vehicle," said Jesse Shoultz, global market manager for Performance Colorants & Ingredients at Milliken & Company. "When incorporated in polyols or added during foaming, this antioxidant reacts into the polymer backbone to deliver reduced VOC emissions and outstanding performance at lower loadings, two very important benefits to customers. By enabling PU foam to meet new, tougher standards for vehicle indoor air quality across the globe, Milliguard AOX-1 antioxidant helps our customers address the latest market challenges."

Test results achieved internally consistently showed Milliguard AOX antioxidant significantly reduced VOC content by more than two thirds to 22 ppm, compared to the industry standard 69 ppm. Milliken's antioxidant also dramatically minimized FOG content emission to only 6 ppm, compared to the industry standard 541 ppm.

The reference method for determination of VOC and FOG levels is the VDA278 standard developed by Daimler and used by BMW, Porsche and Volkswagen. GM/Opel uses the corresponding GM Engineering Standard GMW15634. Additional country-specific standards have been introduced, including China's GB/T 27630-2011 01 March 2012, and Korea's Automobile Management Act Article 33-3.

Milliguard AOX-1 antioxidant is a reactive, carbon-centered radical scavenger used to protect PU polymers, which are exposed to high heat conditions during foaming, from thermal degradation that causes discoloration and physical property failure. Combining Milliguard AOX-1 antioxidant with conventional peroxy and alkoxy radical stabilizers provides ultimate thermal stability. The product interacts synergistically with other antioxidant classes and also reacts earlier in the oxidation cycle to provide unparalleled levels of stability according to Milliken.

Milliken engineered Milliguard AOX-1 additive to be covalently bound with the urethane polymer. This unique approach prevents the antioxidant from migrating to the surface and virtually eliminates VOC and FOG emissions from the final component.

Milliguard AOX-1 antioxidant also reportedly contributes to environmental protection by enhancing the performance of natural oil polyols (NOPs) and non-halogenated flame retardants. The use of NOPs for PU is forecast to grow strongly as the industry strives to include renewable raw materials in formulations according to a report by Transparency Market Research (Natural Oil Polyol (NOP) Market: Global Industry Analysis, Size, Share, Growth, Trends and Forecast 2014 - 2020). However, a major concern is the higher levels of discoloration that result from NOPs. Milliguard AOX-1 antioxidant reportedly provides a solution to this issue by facilitating use of naturally derived polyols without concerns about out-of-control auto-oxidation, helping to encourage greater NOP use.

Similarly, the use of non-halogenated flame retardants can cause increased discoloration in a part, as well as phenol emissions from degradation of phosphate ester flame retardants. However, Milliguard AOX-1 antioxidant has been proven to stabilize non-halogenated flame retardants, reducing both discoloration and phenol emissions.

About the Author(s)

You May Also Like