Sponsored By

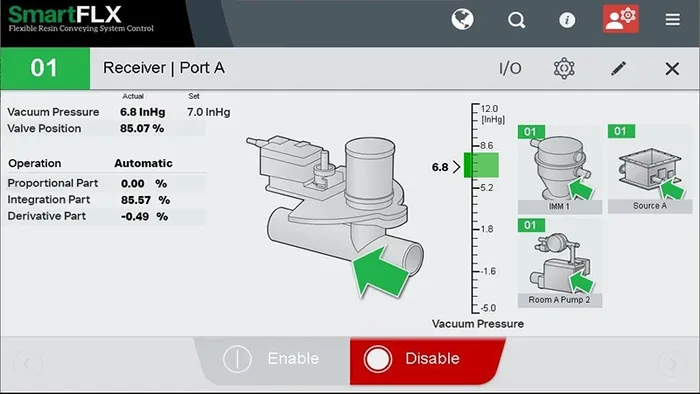

Auxiliaries

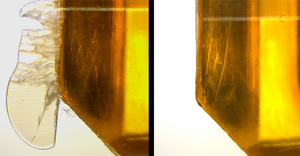

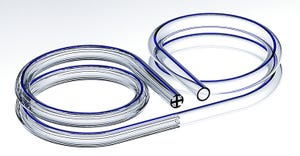

Centerwave 6000 tube and pipe measurement system

Extrusion: Pipe & Profile

Sikora Presents Array of Advanced Plastic Tube and Pipe Measurement SystemsSikora Presents Array of Advanced Plastic Tube and Pipe Measurement Systems

The Centerwave 6000 series measures tubes and pipes ranging in size from 32 to 1,600 mm diameter with the touch of a button.

Sign up for the PlasticsToday NewsFeed newsletter.