Combined with machine learning, HSI classifies compostable and biodegradable plastics with high accuracy for separation from other packaging materials.

March 15, 2023

Separating compostable plastics from conventional plastic waste at recycling facilities is challenging, but researchers in the United Kingdom have developed a method that uses sensitive imaging techniques and machine learning to do so accurately.

The research team, based at the Plastic Waste Innovation Hub and departments of mechanical engineering and chemistry at University College London (UCL), published the results of its investigation in a recent edition of Frontiers in Sustainability.

Compostable plastic is material engineered to biodegrade under controlled conditions.

But compostable and conventional plastics often look alike, so compostables can erroneously enter the recycling stream, causing contamination and reduced recycling efficiently.

In addition, when recyclable, conventional plastic is tossed into municipal compost bins, the compost stream becomes polluted.

The UK team’s approach overcomes these issues, using hyperspectral imaging (HSI) and machine learning techniques that can identify the compostable plastics among conventional plastics.

“[E]ffective sorting technologies for compostable plastics are needed to help improve composting rates of these materials and reduce the contamination of recycling waste streams,” the authors wrote in their research paper.

Hyperspectral imaging sees “chemical fingerprints” for sorting during recycling.

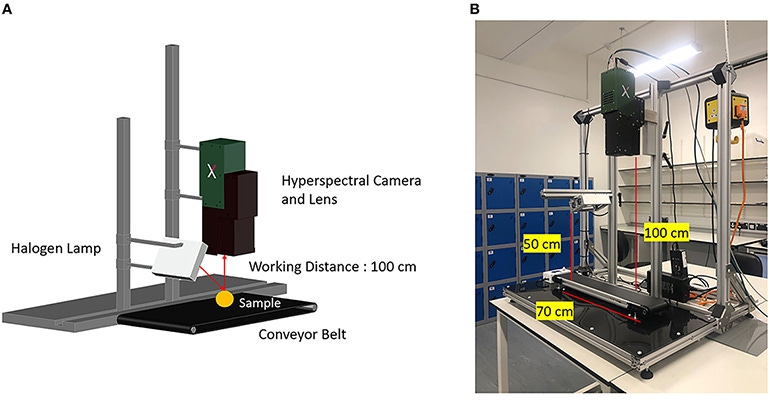

The UCL team used HSI technology — an imaging method that detects the chemical signature of materials while scanning them — to create a classification model that could identify and classify compostable plastics.

A hyperspectral imaging camera and machine learning techniques such as principal component analysis (PCA) and partial least square discriminant analysis (PLS-DA) aided in development of the model.

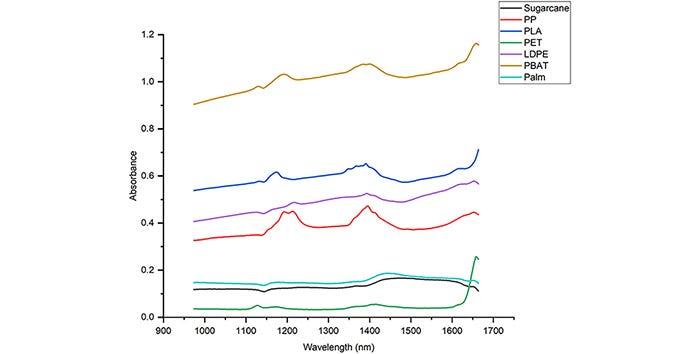

The researchers used these tools to look at a range of materials, including:

Materials derived from biomass, such as sugarcane and palm leaf. These are used to produce packaging.

Compostable plastics, including polylactic acid (PLA) and polybutylene adipate terephthalate (PBAT), which are used to make cup lids, tea bags, and magazine wrappers.

Conventional materials such as polypropylene (PP), polyethylene terephthalate (PET), and low-density polyethylene (LDPE). PP and PET are often used to produce food containers and beverage bottles, and LDPE is used for plastic bags and packaging.

The researchers experimented with plastic pieces measuring from 5-mm square to 50-mm square, and their model achieved 100% accuracy for all materials when the samples were larger than 10-mm square.

However, for biomass-based samples that were 10-mm square or smaller, the misclassification rate was 20% for sugar-cane-derived and 40% for palm-leaf-derived materials.

For the 5-mm-square samples, the model had mixed results: The misclassification rate was 20% for LDPE and PBAT, 60% for sugarcane-derived material, and 80% for palm-leaf-derived material. The model could identify PLA, PP, and PET pieces of all sizes without error.

Raw absorbance spectra of sugarcane-derived packaging, PP, PLA, PET, LDPE, PBAT and palm-leaf-derived packaging acquired by hyperspectral camera.

“Our system is capable of accurately sorting compostable plastics at the typical product scale (compostable spoons, forks, coffee lids) and differentiating them from identical looking conventional plastic items with high accuracy,” the authors stated in their paper.

They also noted that their system’s plastic-classification speed needs to be higher, matching industrial conveyor speeds, before the system will be suitable for industrial composters. Robotic removal of plastics during sorting would be required in industrial settings, as well.

The high cost of HSI technology, compared with current sorting systems, is another impediment to real-world use; HSI cameras are priced from $45,000 to $49,800, according to the researchers.

You May Also Like