Simple measures such as the enclosure of certain line components can result in significant savings in blown film production. However, according to Reifenhäuser Kiefel Extrusion, the amount of savings strongly depends on the component chosen. Tests conducted in the Technology Center of Reifenhäuser Kiefel Extrusion with various raw materials shown that the enclosure of barrels and heater-bands has reportedly proved to be the most efficient measure.

September 19, 2014

Simple measures such as the enclosure of certain line components can result in significant savings in blown film production. However, according to Reifenhäuser Kiefel Extrusion, the amount of savings strongly depends on the component chosen. Tests conducted in the Technology Center of Reifenhäuser Kiefel Extrusion with various raw materials shown that the enclosure of barrels and heater-bands has reportedly proved to be the most efficient measure.

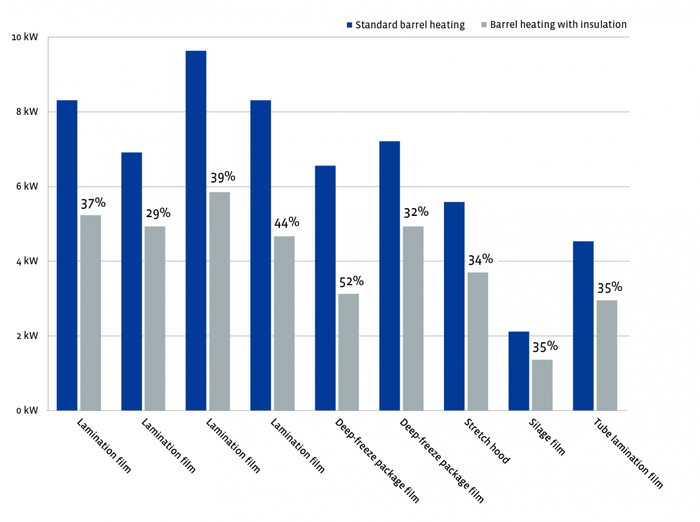

The company claims that the engineers were able to save extruder heat energy between 20 and 50% alone by providing the barrels and heater-bands with insulating sleeves. Specifically, this means that energy savings of up to 100,000 kWh per year can be obtained when encased barrels instead of non-insulated ones are used in a 5-layer blown film line processing resin of 500 kgs/h. These savings result in about 12,000 euros (USD 15,000), depending on the energy costs.

The company believes that the insulation of blown film die is less effective, which was also shown in tests carried out in its Technology Center. Here, the benefit lies only in the starting and heating-up phases of the extrusion line. Reifenhäuser claims that a medium-sized blown film line would generate cost savings of 1,000 euro (USD 1,283) per year. The effects achievable for both insulation applications depend to a large extent on the material used, process parameters and output rate, the company stated.

"Energy costs are no longer a negligible factor in the production of extruded plastic products," said Ralf Pampus, responsible for the subject of energy efficiency within the Reifenhäuser Group. "Within the framework of our Blue Extrusion initiative we are developing concrete measures that can easily be put into practice to provide significant savings for our customers. Thanks to the tests we conducted in our Technology Center, we know exactly which measures will bring the desired effects and which measures will only lead to negligible results."

|

Energy consumption and energy savings obtained with insulation, shown in percent for different extruded products |

|

Insulation installed on extruders |

About the Author(s)

You May Also Like