Engel will tour its recently launched e-mac line of injection molding machines from mid-February through this summer, starting in France, with additional stops in Hungary, the Czech Republic, Poland, and Germany. The Austrian headquartered injection molding machine and automation supplier said the road show will feature production of innovative applications, specialist lectures, and opportunities for one-on-one dialogue with Engel experts.

February 6, 2013

Engel will tour its recently launched e-mac line of injection molding machines from mid-February through this summer, starting in France, with additional stops in Hungary, the Czech Republic, Poland, and Germany. The Austrian headquartered injection molding machine and automation supplier said the road show will feature production of innovative applications, specialist lectures, and opportunities for one-on-one dialogue with Engel experts.

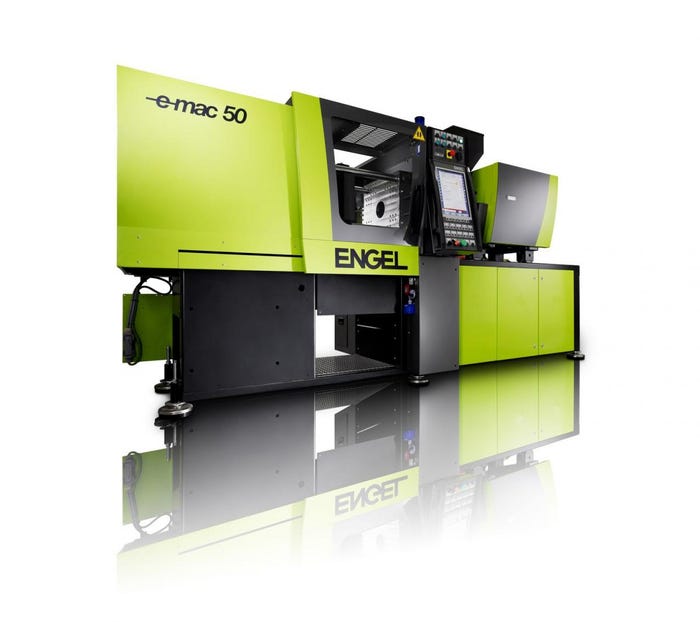

All the e-mac's drives are servoelectric, from injection and metering to mold and ejector movements, resulting in more precision and machine efficiency. Synchronous movements of the drive axes allow fast cycle times, with Engel saying the press's injection axis boasts acceleration of more than 20 m/s². The series currently has four machine sizes with clamping forces of 50, 75, 100 and 180 tons. The machine uses Engel's CC 200 control, and Engel notes that the machine is completely modular and allows automation integration.

Engel e-mac

The road show kicks off in the French town of Wissous (Feb. 12-13). Engel said in a release that it will use two applications to display "the full potential of the machine". One application is a connector housings molded from fiberglass-filled PBT/ASA on an Engel e-mac 310/100 with integrated Engel viper 6 linear robot. Connector contacts are inserted post molding, dimensional stability is a must.

Announced in June 2012, Engel displayed two e-mac's four months following their launch at the Fakuma show in Friedrichshafen, Germany in October.

At Fakuma, an e-mac 50/50 with 50 tonnes clamping force injection molded two-pin PBT plug housings in a 4-cavity mold. The machine used a size 18 screw and the shot weight for the plugs was 3.6g.

Also at Fakuma, an e-mac 310/100 with an integrated viper 6 linear robot produced polypropylene and liquid silicone wine bottle stoppers. By using UV vulcanization, the two materials could be processed in a single step. Engel believes its low-temperature UV vulcanization process "paves the way for new multi-component technology applications."

About the Author(s)

You May Also Like