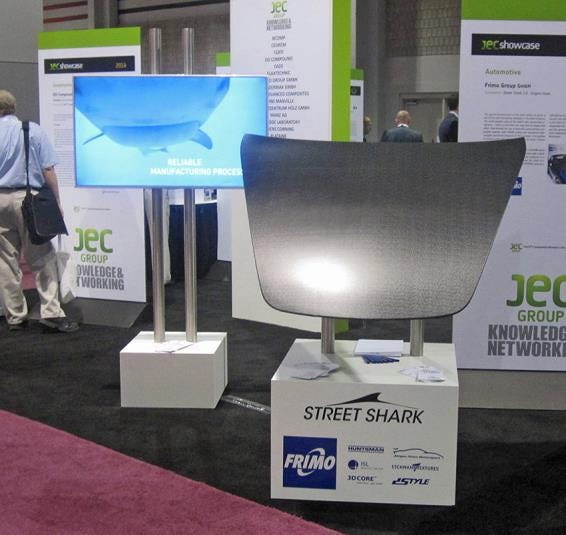

A modified BMW Z4 with an engine hood and roof module constructed from sandwich components with a sharkskin surface won a JEC Innovation Award at the Atlanta-based JEC Americas show this past May.

August 19, 2014

A modified BMW Z4 with an engine hood and roof module constructed from sandwich components with a sharkskin surface won a JEC Innovation Award at the Atlanta-based JEC Americas show this past May.

The project was a joint effort of composites processing concern Frimo (Lotte, Germany) and 3D|Core GmbH & Co. KG (Herford, Germany), a supplier of structure-strengthening foam core with a honeycomb structure that can be arranged in a three-dimensional layout. Frimo's partner also works in the boat building sector. This collaborative project was presented for the first time in 2013 at Composites Europe.

|

Shark skin surface improves aerodynamic performance of composite parts. |

The weight-optimized sandwich design employs an advanced polyurethane (PUR) material from Huntsman called Vitrox as the sandwich matrix system. The resin is suitable for use in high-volume resin transfer molding (RTM) processes.

The RTM process employed can form "bionic surfaces." To make the sharkskin surface, a tool was equipped with a surface geometry molded from a real shark by Eschmann-Textures (Neuenstadt am Koche, Germany), another partner in this project. ISL-Chemie GmbH & Co. KG (Kürten-Herweg, Germany) was responsible for the paint system. The styling and geometry of the vehicle are influenced by racing, and were developed and designed by Dstyle, Inc. (Chula Vista, CA).

The Street Shark has gained increasing market interest since its initial debut according to Frimo. Subsequent trials and optimization such as wind tunnel testing have led to an enhanced Street Shark 2.0, which was presented to the VDI's International Congress - Plastics in Automotive Engineering - in Mannheim in spring in the guise of the Mission 400 Alzen Porsche. The sharkskin structure on the engine hood that was primarily optimized in the Street Shark 2.0, being enlarged in order to further improve performance such as enhanced drag coefficient.

Improvements in drag coefficient identified in the wind tunnel make applications for the rail and aviation industry interesting according to Frimo. Concepts are also being evolved for the boat and shipbuilding sector.

Street Shark technology is also attracting attention from other industries such as wind power, and sports and leisure. Further, besides aerodynamically-efficient sharkskin, it is possible to produce other bionic surface structures such as dirt-repellent or self-healing surfaces, and decorative surfaces such as wood look for the leisure and furniture industries, for example.

About the Author(s)

You May Also Like