At MD&M West in Anaheim, CA, at the beginning of the year, I found myself getting an education in horticulture from scientist Irina Roof of Zeus, a specialist in polymer tubing and material science. As it turns out, the engineering of a medical-grade PEEK that dramatically increased the material's lubricity was inspired by a lotus plant.

November 21, 2014

At MD&M West in Anaheim, CA, at the beginning of the year, I found myself getting an education in horticulture from scientist Irina Roof of Zeus, a specialist in polymer tubing and material science. As it turns out, the engineering of a medical-grade PEEK that dramatically increased the material's lubricity was inspired by a lotus plant.

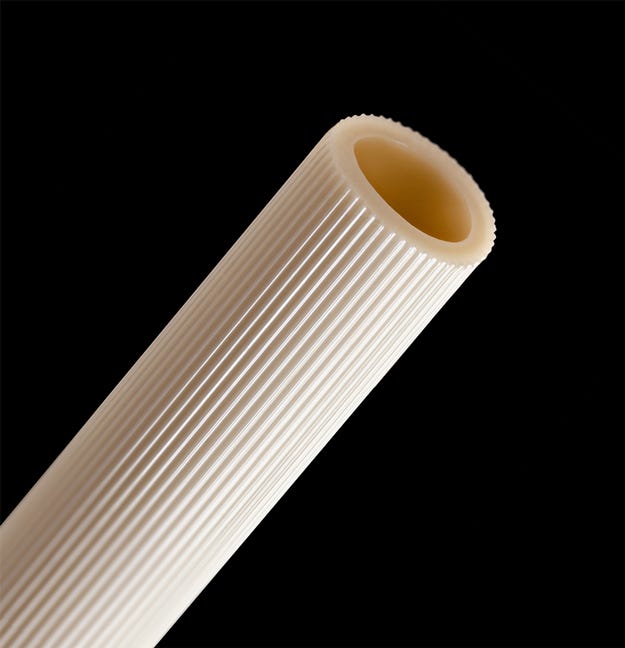

PEEK is remarkably strong but the material does not come close to the lubricity of fluoropolymers. By engineering channels into the tubing, Roof explained, drag force is reduced. It works in much the same way that natural protrusions on the lotus plant and water lilies allow water to bead rather than wet the leaves.

In a recent news release, Zeus announced that independent testing has confirmed that its PEEK Engineered Surface reduced the coefficient of friction by 42% compared with the PEEK control sample.

About the Author(s)

You May Also Like