Sponsored By

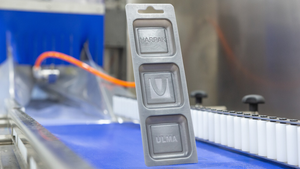

FC1000 IM2 thermoforming machine

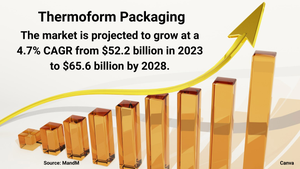

Packaging

Thermoformer Claims Highest Throughput per Square FootThermoformer Claims Highest Throughput per Square Foot

At NPE2024, WM Thermoforming Machines will preview a new thermoforming concept launching later this year.

Sign up for the PlasticsToday NewsFeed newsletter.