Why should you go to ANTEC? Most companies won't even pay for the dues for the Society of Plastics Engineers much less cough up the $1000+ that it will cost for the entry fee, airfare, hotels etc. for the three-day event. But they miss the point.

May 15, 2013

Why should you go to ANTEC? Most companies won't even pay for the dues for the Society of Plastics Engineers much less cough up the $1000+ that it will cost for the entry fee, airfare, hotels etc. for the three-day event. But they miss the point.

Editor's Note: PlasticsToday sent injection molding expert and 45-year veteran of the plastics industry, Bill Tobin to the Society of Plastics Engineers (SPE) ANTEC annual technical conference to get an expert's take on all things injection molding at the event. This is the first installment in a three-part series.

I go to ANTEC for a couple reasons: First is the networking. There are few places where there's a higher concentration of experts in all fields in one place. Many are attendees, some are presenters but there is a wealth of information available just for the asking.

When the 'off shoring' trend went to China the industry took a big hit. When companies hire the new kids, they can learn from books and experience, but the real knowledge comes from 'Bob'. He is the person in a back office who can look at a design (simulated or not) and pick out the faults your computer didn't notice.

He's also the 'Go-To' guy with processing questions. Unfortunately, Bob was one of the first causalities in the wave of downsizing. Now that business is coming back, companies are still hiring the new kids, BUT Bob isn't there. He's retired or selling real estate somewhere. The industry needs to re-grow this Tribal Knowledge. Some of it comes from conferences like ANTEC.

Since ANTEC is an expense that comes (at great sacrifice) out of my own wallet, it is only a good investment in time and money when I can find a few nuggets of information that can answer pesky questions my clients ask. Here are a few:

NUGGET #1-Lot-to-lot resin inconsistencies

Everyone says materials vary lot to lot. Well, they do and they don't.

David A. Okonski, MSR, of GM Research & Development Center (Warren, MI) presented a paper: A Moldflow 2012 Validation Study: Material Properties Versus Simulation Accuracy.

Gala pellets |

Courtesy: Gala Industries |

He showed that about every three years, the rheological properties of materials tend to change. This can be because the reactors change or are updated; the feedstocks can be re-sourced; or the synthesis process has been somehow modified or updated. When you're attempting to predict what a mold will do from any simulation software, knowing your reference library will go out of date, is a problem.

In his study, he found the shrinkage, the processing temperatures, and the viscosity of the plastic during injection tended to stay the same. The interesting changes were the viscosity of the plastic at slow injection speeds.

This is where you do see large variations. To many molders who don't control their processes, this validates the 'It's the same but different' mentality when a new lot of material arrives. However, if you use the principles of scientific molding with as fast as possible fills, it makes little difference.

NUGGET #2-Process simulation as weather forecasting

There were several papers presented showing what you can do (study and implement) with molding simulation programs. These came from the universities, a few companies, and the folks who sell the simulation programs.

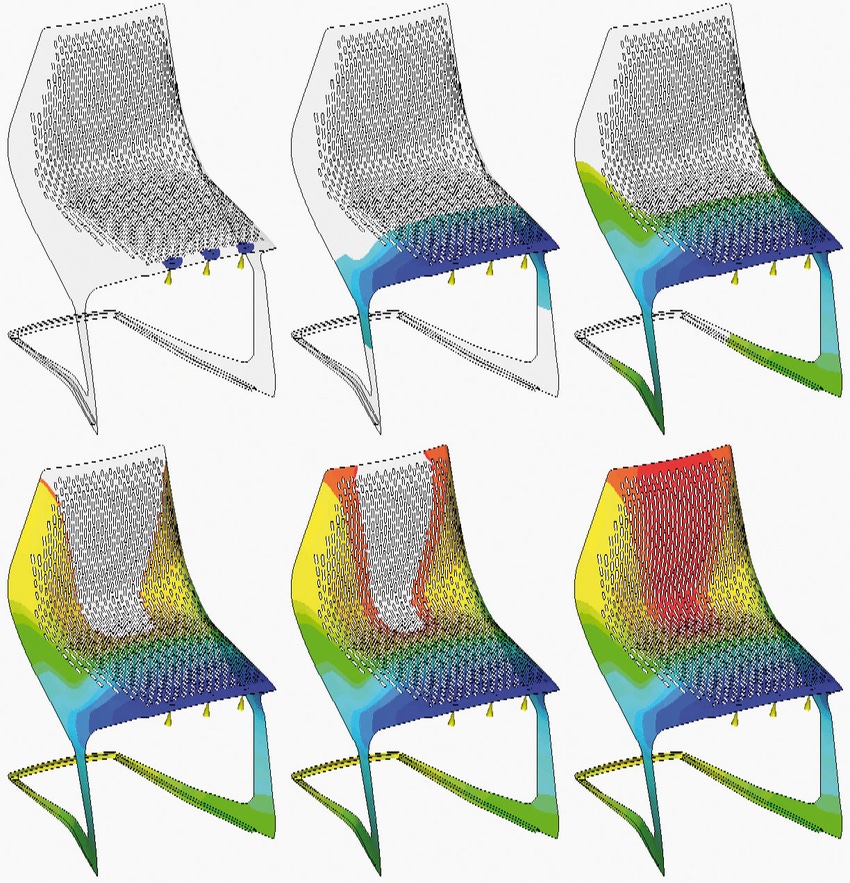

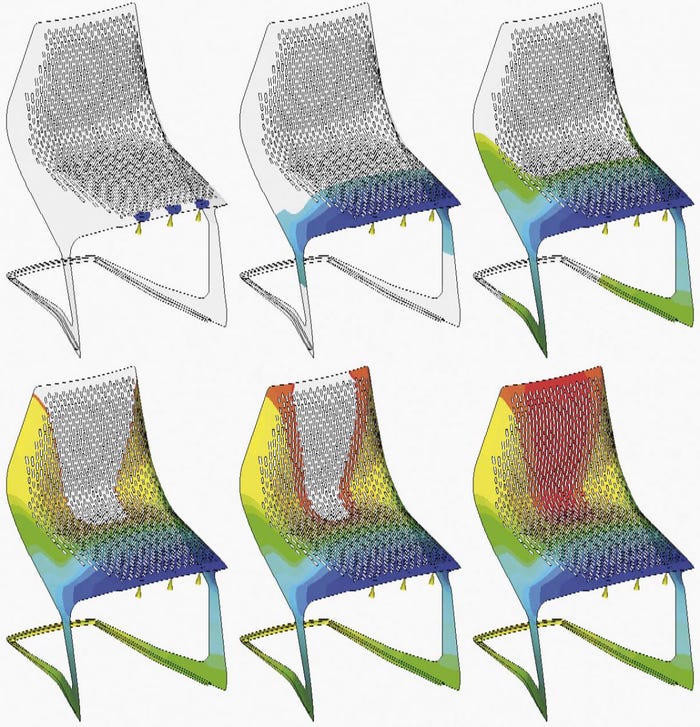

Moldflow chair simulation

As materials become better understood and the simulations get updated, their predictions are more and more accurate in forecasting what will happen in production. When MoldFlow was first introduced it was sometimes described as being 50% efficient. This should be interpreted as: you'd be able to predict and avoid about 50% of the typical mistakes tooling engineers make that cost their companies a substantial amount of money in tooling revisions. As things have progressed, the people who write these programs are saying they are now 80+% efficient.

The nuggets you take away from this are two fold:

First—As David A. Okonski's paper pointed out, the data libraries used are still imperfect both because of the material changes and their inherent inaccuracies. Therefore they still need someone who can read the outputs of the simulations and interpret them properly.

Second—In the Q&A of another session, the presenter of another paper strongly encouraged people who use simulations to validate them in production. Since most companies tend to have a few materials that comprise a majority of their parts, you should pick one or two sample parts and rigidly look at what the simulation predicted; what the mold gave you; and then make the adjustments you need in all parts made from these few materials.

I got to talk with the folks from Autodesk who now own the MoldFlow programs. They likened it to weather forecasting: You have a huge amount of very accurate base-line data. What you don't know is the exact interactions between them. So we rely on mathematical models, and the experience of the people who interpret them.

Simulations are good and getting better. They can almost predict shrinkage values with a good resin library. They are very good at predicting fill characteristics and allow the user to experiment with gate location(s). However, they are not Holy Writ. Simulations work in a 'perfect world' where the mold has perfect heat exchange, the runner system is perfectly balanced, the mold cooling and barrel heats don't cycle up and down, and the machine responds predictably.

Our new generation of designers and engineers have been deluded into believing what's on the computer screen actually happens in the Real World. We are decades away from that being correct. The data from simulations are orders of magnitudes better than having no data at all, but it still takes some experience to understand what it's telling you and how to work with it.

Editor's note: In part II, Bill will review several papers that addressed conformal cooling, including the power of laser sintering, and ball bearings...yes, ball bearings! As you Fletch fans know, "It's all ball bearings these days."

About the author: Bill Tobin's injection molding career began in 1968 at General Motors and has included stops at Ford, Mattel, Hewlett-Packard, and several custom injection molders along the way. In 1975, he founded WJT Associates, which provides design and project engineering consultation on mechanical designs, specification of tolerances, part manufacturability and machine costing, governmental and agency regulatory compliance, budgets and profitability improvement, and expert witness testimony.

About the Author(s)

You May Also Like