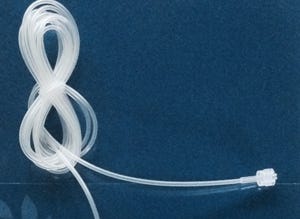

A transparent medical-grade thermoplastic elastomer (TPE) from Teknor Apex (Pawtucket, RI) has been selected to replace PVC in the manufacture of a component used in an anesthesia device manufactured by Vincent Medical (Hong Kong), an FDA-registered contract manufacturer serving global medical device OEMs. Vincent Medical was tasked by its customer to find an alternative to PVC for the extrusion of a gas sampling tube, part of an anesthesia delivery and monitoring assembly.

August 12, 2014

A transparent medical-grade thermoplastic elastomer (TPE) from Teknor Apex (Pawtucket, RI) has been selected to replace PVC in the manufacture of a component used in an anesthesia device manufactured by Vincent Medical (Hong Kong), an FDA-registered contract manufacturer serving global medical device OEMs. Vincent Medical was tasked by its customer to find an alternative to PVC for the extrusion of a gas sampling tube, part of an anesthesia delivery and monitoring assembly. The challenge in making the switch was to match or exceed PVC performance in extrusion, assembly, and clinical handling, said Otto To, General Manager,Vincent Medical. The Medalist MD-585 TPE compound from Teknor Apex met those criteria, he added.

"Teknor Apex was well positioned to work with us and our customer to identify the best alternative to PVC, since it is both a leading producer of medical-grade PVC compounds and the developer of an innovative family of medical-grade TPEs for many of the same applications," said To in a press release announcing the news. "Because the customer has enjoyed a good working partnership with Teknor Apex through years of using Apex PVC compounds, it felt very comfortable evaluating the company's Medalist elastomers for the gas sampling tube."

"Teknor Apex was well positioned to work with us and our customer to identify the best alternative to PVC, since it is both a leading producer of medical-grade PVC compounds and the developer of an innovative family of medical-grade TPEs for many of the same applications," said To in a press release announcing the news. "Because the customer has enjoyed a good working partnership with Teknor Apex through years of using Apex PVC compounds, it felt very comfortable evaluating the company's Medalist elastomers for the gas sampling tube."

Teknor Apex also brought to the project a combination of local and global capabilities, according to Elliott Pritikin, Senior Marketing Manager for Teknor Apex in the Asia-Pacific region. "While our companywide medical team draws on experience in all of the world's key markets, we provide comprehensive support to our Asian customers from our regional headquarters in Singapore and, in the case of Vincent Medical, from our commercial and technical staff in southern China," said Pritikin. "While switching from PVC to TPE posed a challenge to traditional methods of bonding tubing to connectors, for example, our local team collaborated with Vincent Medical at their Donguan, China, plant to develop a connector solution that ultimately exceeded the OEM's requirements."

At the Vincent Medical facility, the Medalist MD-585 compound processed efficiently, exhibiting easy startups, tight tolerances, and high speeds with minimal downtime, according to To. "The consistency of the material supplied to us made it possible to fine-tune our extrusion process and assembly operation," he said. "The surface feel and lubricity of the Medalist-based tube was similar to that of PVC, a benefit for our own operators and the healthcare professionals who will ultimately use the product. Its kink-resistance was also similar to that of PVC, and superior to that of other PVC alternatives," said To.

The Medalist MD-585 compound is part of the Medalist MD-500 series of elastomers, which Teknor Apex developed to be the first fully practical alternatives to PVC in medical tubing. These compounds exhibit crystal clarity and mechanical properties comparable to those of PVC; provide similar clamp resilience and resistance to kinking and necking; have a PVC-like "feel"; and are substantially more flexible and significantly less dense. At the same time they undergo minimal color shift upon heat aging after exposure to gamma irradiation.

Although PVC remains the most widely used polymer in medical applications, concern that plasticizers could leach from the material have led a growing number of healthcare institutions worldwide to seek alternative materials.

About the Author(s)

You May Also Like