Fuel efficiency and carbon-dioxide emission reduction are on the minds of every vehicle designer today as they work to keep their products competitive. One materials company in Germany, PolymerPark Materials (Dresden/Aachen; formerly VarioLineSystems) has introduced a new product line of semifinished construction elements, VarioLine CompositeSandwiches (VCS), to meet these needs.

July 17, 2009

Fuel efficiency and carbon-dioxide emission reduction are on the minds of every vehicle designer today as they work to keep their products competitive.

One materials company in Germany, PolymerPark Materials (Dresden/Aachen; formerly VarioLineSystems) has introduced a new product line of semifinished construction elements, VarioLine CompositeSandwiches (VCS), to meet these needs.

|

|

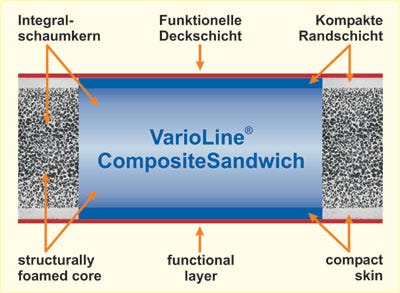

The core of the new material consists of the company’s traditional VarioLine integral foam sandwiches produced of foamed, injection molded polystyrene (PS), polypropylene (PP), or polyethylene (PE) shapes up to 4.5m2 (47.5 ft2) and in thickness of less than 0.4 mm (0.0156 inch). However, in VCS sizes and shapes, external layers of either PP fiber or glass-fiber reinforcing materials are incorporated. According to Ulrike Hoesch-Vial, in marketing at the company, this extends the mechanical properties advantages in lightweight construction of traditional VCS. These include moisture and chemical resistance and flexural strength. The outer reinforcement also provides skid resistance, reduces flammability, and reduces problems associated with marring, scratching, and abrasion.

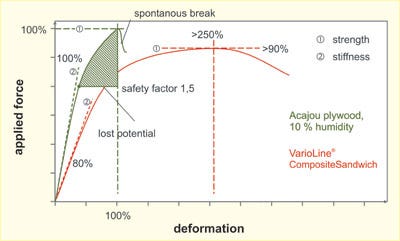

The company is promoting these semifinished products as floor and side panels as well as partition walls in light commercial vehicles, horseboxes, and coaches. Compared to plywood used in such applications, VCS is fully weatherable and is between 30-50% lighter. As an aluminum panel replacement, the new material has the advantage that permanent deformation at stressed points, or dents after hard impact—such as through kicking by horses’ hooves—do not occur.

PolymerPark Materials is offering the pre-fabricated panels in customer-desired cut-outs, special holes, and outer shapes for assembly in a single step. Because these are ready-to-use surfaces, the company says it is not necessary to fit and fasten any other covering layers over the material as protection. —[email protected]

About the Author(s)

You May Also Like