MBA Polymers develops E&E waste into engineering thermoplastic compound

April 29, 2016

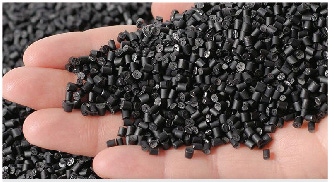

Plastics recycling and technology company MBA Polymers has started what it says it the first commercial production line in the world manufacturing post-consumer PC/ABS pellets from shredded waste from electrical and electronic equipment. The new PC/ABS plant is located at MBA’s facility at Kematen, Austria. The company says it plans to build up production steadily through 2016.

Plastics recycling and technology company MBA Polymers has started what it says it the first commercial production line in the world manufacturing post-consumer PC/ABS pellets from shredded waste from electrical and electronic equipment. The new PC/ABS plant is located at MBA’s facility at Kematen, Austria. The company says it plans to build up production steadily through 2016.

PC/ABS is a highly-engineered blend of polycarbonate (PC) with acrylonitrile-butadiene-styrene copolymer (ABS). It is commonly used in a huge range of electronic products, such as computer monitors, cellular phones and laptop computers, as well as automotive applications. The new product will be distributed under the EvoSource trade name.

According to Richard McCombs, Chief Executive, MBA Polymers, the decision to develop PC/ABS products was driven by the growing demand from customers for post-consumer recycled plastic, as well as MBA Polymers’ commitment to sustainable growth. Post- consumer PC/ABS, is projected to become a vital part of meeting the growing global demand for sustainable materials in some of the largest markets in the world. “These are exciting times for our engineering plastics business,” said McCombs. “Every 1% increase in the usage of our waste benefits our return on investment enormously.”

The company claims that EvoSource PC/ABS grades have excellent mechanical properties that make them candidates for a broad range of applications including some in the automotive, electrical, industrial and consumer markets. “EvoSource PC/ABS and MBA Polymers’ other high-quality recycled plastics further expand the opportunities for manufacturers to use more sustainable materials, which in turn increase the realities of a circular economy,” explained Arthur Schwesig, Business Manager, Engineering Plastics, MBA Polymers, Austria.

In electronics, for example, designers will be able to specify Evosource PC/ABS to increase the use of post-consumer recycled plastics to achieve the higher ratings in the Electronic Product Environmental Assessment Tool (EPEAT), a global electronics registry that rates mobile phones, televisions, printers, copiers and other imaging equipment, and computers and displays.

With locations in China, UK and Austria, MBA Polymers is the world leader at producing high value plastics from end-of-life durable goods. It saves over 80% of the energy and between 1- 3 tons of CO2 for every ton of virgin plastic it replaces.

In addition to the new PC/ABS product, the company produces a variety of post-consumer  plastics recovered from shredded WEEE and end-of-life vehicles. These products are sold into a broad range of industries including the automotive, electrical, industrial and consumer markets. Its premium EvoSource ABS (Acrylonitrile/Butadiene/Styrene) and HIPS (High Impact Polystyrene) grades are currently used in products such as printer housings, coffee makers and vacuum cleaners.

plastics recovered from shredded WEEE and end-of-life vehicles. These products are sold into a broad range of industries including the automotive, electrical, industrial and consumer markets. Its premium EvoSource ABS (Acrylonitrile/Butadiene/Styrene) and HIPS (High Impact Polystyrene) grades are currently used in products such as printer housings, coffee makers and vacuum cleaners.

About the Author(s)

You May Also Like