Cost-effective and fast configuration process with ScrewCon 3

June 2, 2016

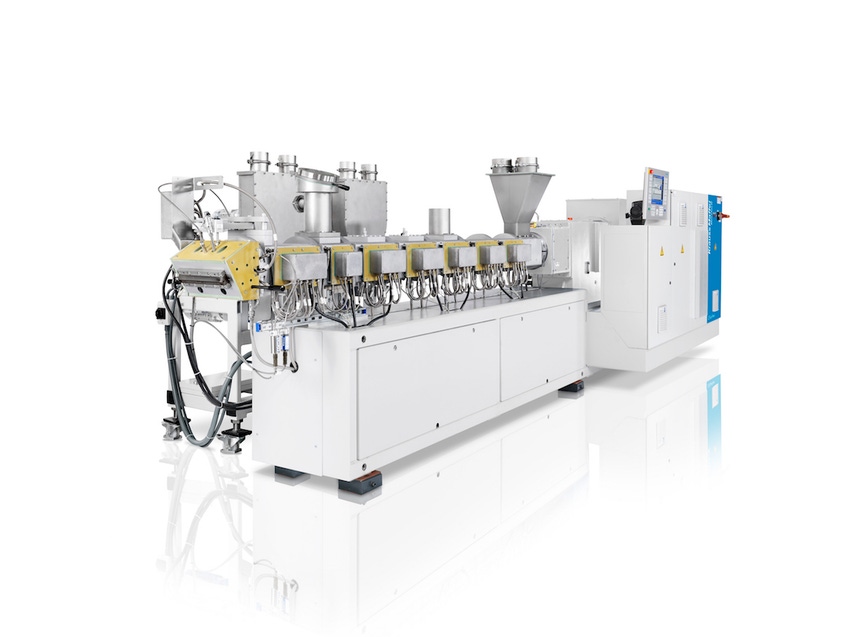

KraussMaffei’s ScrewCon software has been the stalwart tool for configuring the screw and housing elements of twin-screw extruders for over 20 years. An in-house development of KraussMaffei Berstorff, this software has already undergone two updates and the company has now released the third. ScrewCon 3 comes with a completely new user interface and numerous new functions and has been available to customers as from April 2016, it is also available to our customers.

With a library of about 2,000 screw and barrel housing elements for users to choose from, ScrewCon 3 offers an impressive array of resources. Elements for the different twin-screw  extruder sizes in the ZE BluePower, ZE UTi, ZE UTXi and ZE Basic series are all available.

extruder sizes in the ZE BluePower, ZE UTi, ZE UTXi and ZE Basic series are all available.

“Customized configurations for specific requirements and individual machines can be prepared within a minimum of time," says Andreas Madle, who is responsible for process-engineering developments at KraussMaffei Berstorff and in charge of the complete redesign of the ScrewCon software. "In addition, the configuration process is extremely simple using the click and drop function."

ScrewCon 3 is a Windows-based solution featuring a high level of user friendliness. Owing to the intuitive operator guidance, no specific previous knowledge is required to use the software. In combination with the extensive portfolio of integrated features, this makes ScrewCon 3 the ideal tool for designing and documenting the set-up of twin-screw extruder processing sections.

The clear and true-to-scale visualization of screw and housing elements substantially reduces the time required to prepare tailored configurations. As the two elements are directly displayed below each other, screws and barrel housings can be perfectly adapted within shortest time. The user will instantly be able to see whether the two selected elements match or not. In addition, the screw elements can be precisely positioned relative to the barrel housing openings.

One of the newly added element in version 3 of the ScrewCon software is the inventory management feature for screw and barrel housing elements, which, says the company, offers added benefits to customers. While configuring the extruder set-up best suited to the current requirements, users can automatically view the available stock of elements needed for their purpose and will thus immediately see whether the desired configuration can be implemented or not. Hence, ScrewCon 3 can significantly accelerate the configuration process of twin-screw extruders, thus significantly increasing the cost-effectiveness of this versatile tool.

added benefits to customers. While configuring the extruder set-up best suited to the current requirements, users can automatically view the available stock of elements needed for their purpose and will thus immediately see whether the desired configuration can be implemented or not. Hence, ScrewCon 3 can significantly accelerate the configuration process of twin-screw extruders, thus significantly increasing the cost-effectiveness of this versatile tool.

A further highlight of the new ScrewCon 3 software is the simultaneous on-screen display of right and left screws of the twin-screw extruder. Each screw can thus be individually designed and even different elements can be selected for the two screws, if required. In this case, system visualization also helps to avoid installation errors when configuring left and right screws with different screw elements.

About the Author(s)

You May Also Like