Magnetic QMC: Faith in physics helps turn molds around quickly

September 1, 2001

|

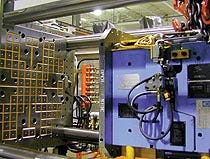

The pursuit of lean perfection at Textron Automotive Co.'s Westland operation is facilitated by its magnetic QMC systems, which allow molds weighing up to 40 tons to be changed in less than 30 minutes several times per shift. |

Changing up to 30 active molds weighing up to 80,000 lb on 18 400- to 3000-ton molding machines up to eight times every shift is a task some may not be up to. But for Textron Automotive Co.'s (TAC) Westland operations, a lean automotive trim molder in Westland, MI, such changeovers are routine. Folks on the floor add that they are confident that their target changeover time of less than 30 minutes per mold can be achieved, even for their 40-ton molds.

Along with other TAC operations, Westland has set its sights on certification under the Society of Automotive Engineers' SAE J4000 standard. The standard tests compliance with lean manufacturing principles (see www.sae.org for more information).

Eliminating muda (Japanese for waste), like the waiting and inventories involved in mold changing, is an important part of Westland's leaning. Muda is a popular word in lean lingo. Waste is any activity that consumes resources but creates no value. Lean perfection is the elimination of all waste.

Small-lot production of only what is requested by the next production step is a major lean principle. Understandably, quick mold change (QMC) can be essential. Presently, 12 Westland presses are equipped with permanent-magnet QMC systems from Tecnomagnete Inc. (Troy, MI). Soon they all will be, according to George Stocks, lead process engineer. "There was skepticism around here at first. Hanging an 80,000-lb mold in a machine with nothing visible supporting it was a concern for me and my staff," he says. "But we've had no issues with mold slippage or installation."

|

Tecnomagnete's Quadpress QMC systems are as green as they are lean. They save energy and operate without using any hydraulics, features that are important to ISO 14000-certified plants like Westland. |

One-touch Setup

Instead of backplates, Tecnomagnete's ergonomic Quadpress QMC systems use magnetic machine platens configured to global industry-standard patterns. Only 1 second of electrical power changes the polarity of the magnetic platens, enabling them to generate a permanent holding force equivalent to 10 percent of press clamping force. Another 1-second charge demagnetizes the mold for removal. No one has to risk climbing up on a press to bolt down a mold, and it will not fall out in the event of a power loss.

Also, since the magnetic field extends only 5/8 inch from the surface of the magnetic platen into the mold, it does not interfere with mold actions. The system's redundant safeties are invisible to the user, who has but to push a single button for setup. Quadpress systems cost about $50 per ton—$50,000 for an 1100-ton press. Tecnomagnete reportedly has sold 3000 worldwide, 600 in North America.

Westland plans to change its big molds in 30 minutes or less. The company also plans to take 10 percent off the changeover clock every year. That will surely reduce the muda of waiting. As far as inventory muda goes, TAC's company-wide goal presently is 50 turns/month. Westland reportedly achieved 51.6 turns in June. Its QMC systems are helping to empower confidence in its relentless pursuit of lean perfection.

Contact information |

You May Also Like