Molders Economic Index: Setting the stage for solid global growth in 2009

Current economic news is universally grim. Much of Europe is sliding into a no-growth or negative growth pattern and even sterling performers with massive growth such as India and China report slower manufacturing output.The culprits across the board are high energy costs (not withstanding the August decline in oil prices), a declining housing market, growing unemployment or “underemployment,” and the lack of financing available from banks for the unavoidable restructuring of global manufacturing.

September 26, 2008

Current economic news is universally grim. Much of Europe is sliding into a no-growth or negative growth pattern and even sterling performers with massive growth such as India and China report slower manufacturing output.

The culprits across the board are high energy costs (not withstanding the August decline in oil prices), a declining housing market, growing unemployment or “underemployment,” and the lack of financing available from banks for the unavoidable restructuring of global manufacturing.

Restructuring manufacturing

More severe than the housing and credit crisis is the already-apparent credit crunch faced by manufacturers worldwide. This includes injection molders and they, along with all other manufacturers, face up to what will probably be the most profound change in manufacturing in the last 20 years.

For 2008, according to estimates by the European Union in Brussels, about €341 billion more will be spent on a global basis by companies that are involved in shipping (trucks, cargo ships, and rail).

For decades, manufacturing moved to the lowest-labor-cost countries in order to save on wages, which make up a solid portion of all manufactured goods. It was and still is to some extent more affordable to manufacture computers in Malaysia or China and then ship to consumers in Europe or North America.

This is changing and must change. Until 2006, transportation costs were almost a rounding error on the balance sheets of major consumer products companies such as carmakers or firms like Sony and Dell.

The sharp rise in oil and gas prices has changed all that. Transporting goods does cost more and destroys profit margins. It is not only transportation costs that bite hard, but also energy to operate a molding plant and high resin costs. On average, all grades of polyethylene have gone up by $0.07/lb since July 1.

Note here that the increase in oil and gas prices has forced “low-cost exporters” such as China, India, Indonesia, and the Philippines to impose, on average, 6-7% price increases on exported manufactured goods, according to a World Bank survey that measures the first six months of 2008.

Take this real-life recent example: A major Canadian car parts maker trucked 48 containers of injection molded auto components from the Windsor, ON area to the Port of Halifax. There these containers were loaded aboard a large cargo vessel and shipped south to Mobile, AL, and then trucked from there to several German and Asian car assembly plants.

The value of each container’s products was about $18,700. The transportation costs (trucks and shipping) added $4899.07 to each container load. This was in July 2008. In 2006 the transportation cost would have been just $1760.65 per container.

Global exports have also slowed. Data from global shipping line Hapag-Lloyd show that the average modern container ship—loaded with about 9000 containers—can save about one-third of oil and energy costs by slowing steaming speeds from 23.5 to 20 knots. The downside is that a typical transport from China to Europe or from India to the U.S. West Coast will take three or four days longer.

Oil prices are likely to hover between $115/bbl and $165/bbl for the next few years. In part, oil prices are driven by the value of the U.S. dollar: As that currency rises in value, oil prices go down. But oil and gas costs will remain high.

This is where restructuring comes in and the foresight of Japanese carmakers serves as an instructive example. It makes more economic sense to have components manufactured very close to an assembly plant—within 20 miles or less—to avoid excessive transportation costs. This demands a continued high investment in new manufacturing capacity (molding machines, decorating equipment, and the like) and this strains injection molders already battered by declining profits.

No single product category is exempt. Major grocery chains are restructuring in the United States to buy more local produce to avoid trucking vegetables from California to New Jersey. Computer makers are contemplating small satellite assembly plants with nearby “micro molding” plants close to major consumer markets.

Will injection molders be able to afford the investment in new machines and plants? They have to—to stay in business. The crunch comes because financial institutions are short of cash now to advance the massive financing needed for this restructuring.

Some molders manage. For instance, Accelerated Plastics LLC of Hudson, WI is now adding capacity to mold electronics and medical parts to serve mostly nearby assembly plants.

Other “restructuring” is the almost unavoidable decline in global parts exports and imports. How much longer will it make sense to ship a container of low-priced toys or sporting goods from a Chinese port to the Port of Long Beach, CA? Average costs per 40-ft container for this trans-Pacific voyage have jumped from an average of about $1800/container to $4000/container, including fuel surcharges.

Current economic news

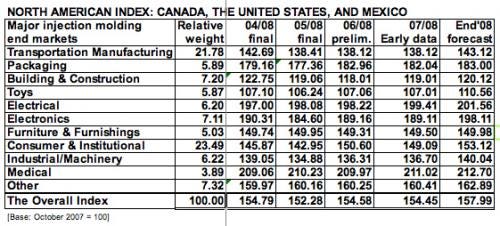

Here is a roundup of current U.S. economic news. Critical here is that the United States is likely to have avoided a traditional recession and will show slow, yet sustainable, GDP growth of 2.5-3% in the second half of 2008 and a touch more in 2009. Economies in Mexico and Canada will display a similar performance.

Orders for U.S.-made factory goods jumped 1.7% in June on stronger demand for machinery, metals, and electrical equipment, and on higher prices for petroleum, the Commerce Dept. reported. Commerce also revised May orders to a higher 0.9% rate, up from 0.6%. These are not figures of a recessionary economy.

Commerce also reported that orders for durable goods rose 0.8% in June while actual shipments and orders for nondurable goods increased 2.5% on the month. Excluding a 2.7% drop in orders for transportation goods, orders rose 2.3%. Meanwhile, shipments of factory good increased 1.6% in June.

Commerce data also show that inventories grew 1% in June, marking the ninth gain in the past 10 months. The inventory-to-shipments ratio fell to 1.22, indicating that factories have extremely lean inventories, which is ultimately good for the future of the manufacturing economy as new orders are now likely to increase.

Somewhat positive was a report for May that the supply of homes at the current sales rate fell to 10 months’ worth from 10.4 months in May. There were 426,000 homes for sale at the end of June at an annual pace, the fewest since December 2004. The figure was down 5.3% from the prior month, the biggest decline since November 1963.

However, an August report from the National Assn. of Realtors showed existing home sales fell 2.6% in July to a 4.86 million-unit annual rate, the lowest level in a decade. The median home price dropped 6.1% from June of last year.

The U.S. GDP grew 1.9% in Q2 2008 based on initial U.S. government data. The same data showed a revised decline of 0.2% for Q4 2007, the first such contraction since 2001. The first quarter GDP estimate was revised downwards by the Commerce Dept. to 0.9%. One possibility is that the United States was in a brief recession in late 2007 but has since emerged from negative growth. However, it will take many months of revisions before we have solid clarity on actual economic performance.

July may have been a month with no tangible growth in manufacturing. According to the monthly index issued by the Tempe, AZ-based Institute for Supply Management (ISM), the ISM manufacturing index slipped from 50.2 in June to 50.0 in July, indicating an equal number of firms said business was growing as said it was slowing. The ISM has been near 50 for 10 straight months, as strong export growth has offset weaknesses in housing and automotive.

The official ISM release did say, however, that inflation “continues to haunt manufacturers. The prices-paid index slipped to 88.5 from 91.5. One chemical firm said it was ‘almost impossible to keep up’ with price movements, while a plastics maker said ‘competitive market forces are preventing companies from boosting prices high enough to recover raw material input costs.’”

Bleak automotive data

Probably the most interesting question right now is if U.S. consumers will again display a short-term memory and use the August decline in oil tabs to buy large SUVs and light trucks. This has happened before and has always been beneficial for molders who sell substantially more injection molded parts on a pound basis for such vehicles as opposed to the smaller and more fuel-efficient compacts and hybrids.

But July sales data show that America’s love affair with heavy SUVs and light trucks may be at an end. In July, car and light truck sales fell to their lowest level in 16 years. Overall sales were down 13.2% and each of the five largest carmakers reported sharp declines. The industry’s annualized U.S. sales rate of 12.55 million units was its lowest since April 1992.

Ford’s sales were down 14.7%, GM’s were down a startling 26.1%, and Chrysler saw sales plunge 28.8% and is now close to being just number six in the ranking of U.S. carmakers.

Toyota reported an 11.9% decline, while Honda, which builds fewer trucks than others, saw July sales decrease 1.6%. Nissan’s sales rose 8.5% on strong demand for its small cars.

Consumers also found that credit for new cars was harder to obtain, and this also sharply impacted car sales.

Molders are making adjustments. The brand-new (2001) Cortland, OH molding plant of Delphi’s Packard Electric unit is now shutting down, and operations—on a smaller scale—are consolidated in Delphi’s Vienna, OH plant.

In contrast—also an example of locating molding operations very close to the actual assembly plant—Hanwha L&C Corp. (Opelika, AK) in July announced plans to almost double molding operations to supply South Korean Kia Motors in West Point, GA. And Hyundai Mobis Group is now investing more than $60 million in West Point for a new plant that makes car bumpers, dashboards, and major subassemblies for Kia.

Along these lines, Toledo, OH-based Dana Holding Corp. just now opened a new molding plant in northern Mexico to make parts for automotive assembly plants just north of the border.

Slower growth in China

The first solid indicators of a tangible slowdown in China’s manufacturing have appeared, according to a brief report issued by the China Federation of Logistics & Purchasing on Aug. 1. China’s Purchasing Managers’ Index fell to a seasonally adjusted 48.4, down from 52 a month earlier and the first time it has fallen below 50 since reports began in 2005.

This slowdown may be a result of the massive shutdown of factories in China to help with smog during the Olympics. But, many speculate, it may point to the first sign that China’s economic imbalances are starting to hurt. For instance, to boost exports, the Chinese government raised the export rebate tax for the flagging textile industry in July.

Higher labor costs, a credit crunch in China, and the toll of high oil prices may actually lead to a decline in export growth in the next few months.

The toll of energy costs on consumer spending is substantial. In the first five months of 2008, German consumers had to spend €22.4 billion more for energy than in the same period last year.

Declines in Europe

Across Europe and specifically in the euro zone, economists anticipate a recessionary climate due to sliding housing markets, escalating energy costs, slower exports, and rising unemployment.

July data, for instance, showed that Spain has gone from an $8.2 billion budget surplus to a $7.39 billion deficit in the past year, according to the Spanish treasury department. Spain’s government now projects full-year GDP growth declining to 2% for all of 2008 after reaching 3.8% in 2007. Unemployment is projected to jump to 11% in 2008.

Europe’s major problem is that the strong euro, which gave up some ground to the U.S. dollar in August, combined with high oil prices (denominated in the U.S. dollar), created a climate in which exports declined and domestic consumption contracted.

Germany’s ZEW institute, the country’s main economic think tank, stated on July 15 that its monthly index of investor expectations of the German economy fell to –63.9 in July, a record low.

Europe was marked in May by an overall 1.9% drop in industrial production, the largest such decline in more than 16 years. Germany, Spain, and France saw industrial production drop a sharp 2.6%. Data from Brussels show inflationary pressures (mostly due to energy costs): In the 12 months ending June 2008, Europe-wide inflation hit 4%.—[email protected]

About the Author(s)

You May Also Like