Barely-there condoms made with Australian native grass

Scientists in Australia have discovered that a tough, spiky variety of native grass can be used to make condoms that are reportedly “as thin as a human hair”—without any loss in strength. Fibers from the Australian native spinifex grass, which thrives on the poorest, most arid soils Australia has to offer, can significantly improve the physical properties of latex. These researchers are convinced that, with a slight refinement of the technology, they can engineer a latex condom that is about 30% thinner, but will still pass all standards.

February 16, 2016

Working in partnership with Aboriginal traditional owners of the Camooweal region in north-west Queensland, the Indjalandji-Dhidhanu People, researchers from The University of Queensland have developed a method of extracting nanocellulose—which can be used as an additive in latex production—from the grass.

Working in partnership with Aboriginal traditional owners of the Camooweal region in north-west Queensland, the Indjalandji-Dhidhanu People, researchers from The University of Queensland have developed a method of extracting nanocellulose—which can be used as an additive in latex production—from the grass.

Professor Darren Martin from UQ’s Australian Institute for Bioengineering and Nanotechnology (AIBN) described the spinifex nanocellulose as a “flexible nano-additive,��” which therefore allowed the research team to make a stronger and thinner membrane that is supple and flexible. .

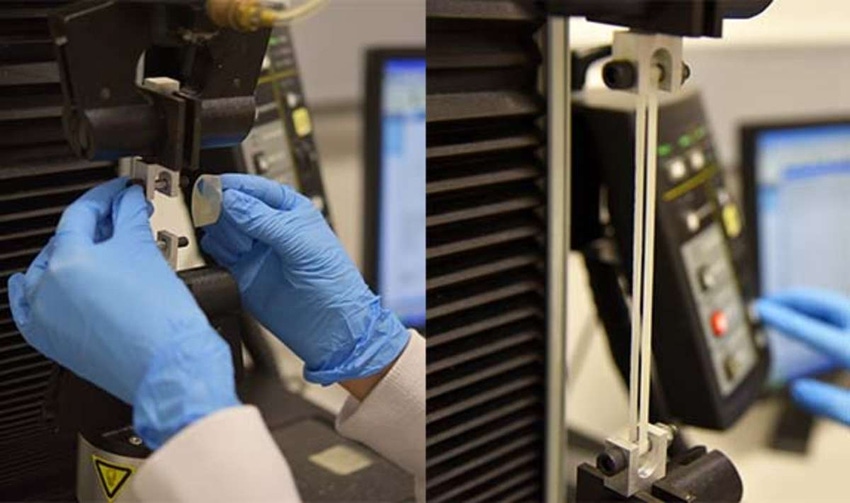

“The holy grail for natural rubber,” he said. "We tested our latex formulation on a commercial dipping line in the United States and conducted a burst test that inflates condoms and measures the volume and pressure, and on average got a performance increase of 20% in pressure and 40% in volume compared to the commercial latex control sample.”

“Late last year we were able to get down to about 45 microns on our very first commercial dipping run, which is around the width of the hair on your head.”

Professor Martin said the benefits of the nanocellulose technology would interest latex manufacturers across the multi-billion-dollar global market.

“Rather than looking at increasing the strength, companies would be looking to market the thinnest, most satisfying prophylactic possible,” he said.

And the technology offers benefits in other application areas, as well. The new material would, for example, make it possible to produce latex gloves that are just as strong, but thinner, giving a more sensitive feel and less hand fatigue to users such as surgeons.

“Because you would also use less latex, your material cost in production would potentially drop as well, making it even more attractive to manufacturers,” Professor Martin pointed out.

AIBN’s Dr Nasim Amiralian said the nanocellulose could be converted from spinifex using an efficient chemistry method.

“You would firstly hedge the grass, and then it would be chopped up and pulped with sodium hydroxide—and at that stage it just looks like paper pulp,” Dr. Amiralian said.

“Then you hit it with mechanical energy to force it through a very small hole under high pressure to peel the nano-fibers apart from the pulp, into nanocellulose happily suspended in water and ready to add to things like water-based rubber latex,” she said.

Spinifex has long been used as an effective adhesive by indigenous communities in Australia. One traditional use of spinifex resins by these communities was for attaching spear heads to their wooden shafts. UQ and the Dugalunji Aboriginal Corp. (DAC) have therefore signed an agreement to recognize local Aboriginal traditional owners’ knowledge about spinifex and to ensure that they will have ongoing equity and involvement in the commercialization of the nanocellulose technology.

DAC Managing Director Colin Saltmere said the technology provides an opportunity for the partners to establish themselves as leaders in the area of spinifex harvesting and processing and the supply of a range of nanocellulose and other spinifex-derived products.

“There are strong hopes of cultivating and processing spinifex grass on a commercial scale, bringing economic opportunities to the remote areas across Australia where it thrives,” Mr. Saltmere said.

“We’re very excited by the prospects of commercializing the technology to provide an entirely new industry to regional Australia.”

UQ’s commercialization company UniQuest has provided support for the development of the nanocellulose technology and funding through its Pathfinder initiative.

About the Author(s)

You May Also Like