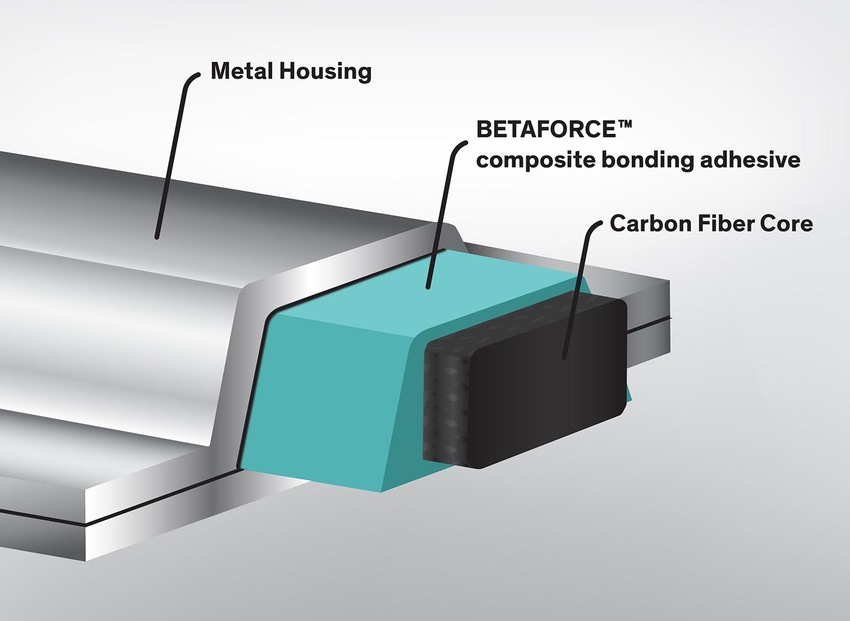

Composite bonding adhesive joins carbon fiber core to metal

May 5, 2016

Dow Automotive Systems has extended its technology for carbon-fiber bonding solutions by adding an injection bonding technique for Betaforce composite bonding adhesives. This development should enable the wider application of carbon-fiber parts in mixed-material assembly and thus supports manufacturers’ lightweight strategies, such as those at BMW Group with its recent BMW 7er series.

|

New adhesive system joins carbon fiber composite to metal. |

Injection bonding can be used to bond carbon-fiber parts to metal in side-frame applications along the roof. Here, the carbon-fiber part is used as an inlay in a metal housing running along the A-pillar into the roof and down the D-pillar. This ensures stability of the passenger compartment in the case of a side-pole impact or rollover, as well as increasing vehicle torsional stiffness while improving subsequent ride-handling and NVH at the lowest mass.

The challenge of integrating such long carbon-fiber composite parts is the management of the differential coefficient of linear thermal expansion (CLTE) along the assembly as well as during the operative life of the vehicle. Betaforce technology helps address that challenge.

Based on a two-component polyurethane structural adhesive technology, Betaforce is characterized by a high elongation factor and outstanding modulus. While the high modulus provides the needed stiffness, the elongation factor enables a high level of energy absorption and flexibility to manage differential CLTE. To achieve the joining of both materials, the adhesive is injected by a robot and surrounds the carbon fiber for a durable bond joining different substrate components. Additionally, Betaforce reportedly provides superb adhesion to multi-material substrates, such as carbon fiber or coated metal, enabling advanced lightweight solutions for automotive manufacturers such as BMW Group.

Materials that can be joined by Betaforce include carbon fiber with coated steel and with coated aluminum. Application areas include roofing, complete carbon-fiber compartments or hang-on parts, such as doors.

You May Also Like