Reverdia collaborating with Wageningen UR on development of bio-PBS

May 20, 2016

A joint development program on biobased PBS (polybutylene succinate) compounds for injection molding has been launched by Wageningen UR Food & Biobased Research and biosuccinic acid producer Reverdia, both of the Netherlands. Traditional PBS is a biodegradable aliphatic polyester produced from fossil-based succinic acid and butandiol. The present project – called APPS, or Novel Applications for Biobased PolyButylene Succinate - will explore the development of durable bio-PBS compounds based on Reverdia’s Biosuccinium. Reverdia, the joint venture between Royal DSM and Roquette Frères, the French global starch and starch-derivatives company relies on low pH yeast technology rather than bacteria to produce its 100 percent biobased succinic acid. The proprietary process does not produce salts as waste and enables customers to produce products with substantially lower environmental footprints.

A joint development program on biobased PBS (polybutylene succinate) compounds for injection molding has been launched by Wageningen UR Food & Biobased Research and biosuccinic acid producer Reverdia, both of the Netherlands. Traditional PBS is a biodegradable aliphatic polyester produced from fossil-based succinic acid and butandiol. The present project – called APPS, or Novel Applications for Biobased PolyButylene Succinate - will explore the development of durable bio-PBS compounds based on Reverdia’s Biosuccinium. Reverdia, the joint venture between Royal DSM and Roquette Frères, the French global starch and starch-derivatives company relies on low pH yeast technology rather than bacteria to produce its 100 percent biobased succinic acid. The proprietary process does not produce salts as waste and enables customers to produce products with substantially lower environmental footprints.

“An important objective of the project is to develop plastics from renewable raw materials with a much wider scope for application, and thus a larger market potential,” said Karin Molenveld of Wageningen UR.

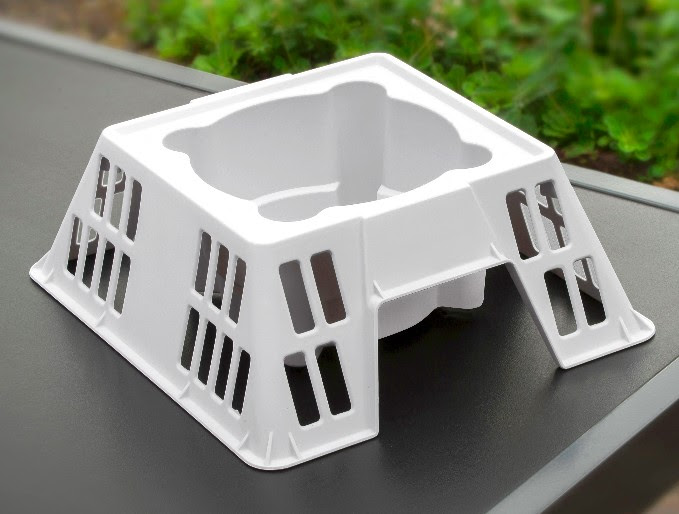

Development will therefore specifically focus on durability, toughness, dimensional stability, thermal and chemical stability, and processing characteristics. Plastic product manufacturers such as RPC Promens and Teamplast will collaborate to validate the compounds in reusable horticultural crates and rigid food packaging with hinges. The final compounds are expected to have an improved carbon footprint in comparison to polypropylene, which is typically used for these applications, without negatively impacting the properties of the material.

“Raw material producers and manufacturers of the final products will test these new materials, ensuring that consumers will soon have biobased and durable plastics in their hands,” said Lawrence Theunissen from Reverdia. “The whole value chain is involved in developing these materials.”

The project is part of the large-scale Biobased Performance Materials (BPM) research program. The goal of the program is the development of high-quality materials based on biomass. Increasingly, as the demand grows, these materials are finding commercial application. The BPM program is focused on two types of materials: polymers produced by plants themselves and polymers made from biobased building blocks derived via biotechnology or chemical catalysis. The annual BPM symposium, in which the program’s latest results and developments are presented, takes place this year on June 16th.

Image courtesy of RPC Promens

About the Author(s)

You May Also Like