Reifenhäuser Introduces Ultrathin Coating Technology for Film and Nonwoven Composites

The patent-pending process, suited for the production of medical protective garments, reportedly slashes film grammage by 66% and overall material consumption by 28%.

March 14, 2022

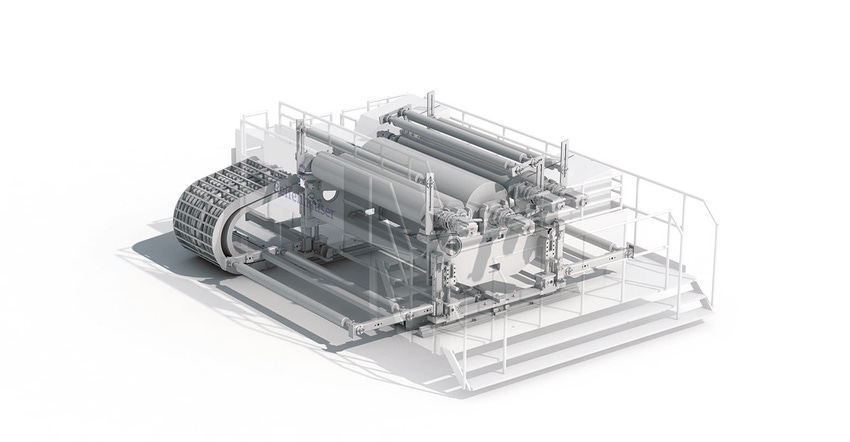

Reifenhäuser Cast Sheet Coating, specializing in cast film, sheet extrusion, and extrusion coating lines, reports that it has developed a new production process for cost-effective film and nonwoven composites with exceptionally low grammage. The company is featuring the technology at the International Converting Exhibition in Munich this week.

The Ultrathin Coating process is suited, in particular, for medical protective garments. The patent-pending process reportedly slashes film grammage by 66% and overall material consumption by 28%. Manufacturers can achieve up to 34% in cost savings compared with conventional production methods through various innovations, such as the elimination of hot-melt adhesives, which simultaneously reduces line-maintenance down time.

"We are currently experiencing a sustained increase in demand for medical protective clothing combined with a return to local production capacity,” said Mark Borutta, Sales & Marketing Specialist at Reifenhäuser Cast Sheet Coating. “Against this backdrop, producers achieve a fast return on investment and high profitability with Ultrathin Coating, even when production is based in Europe."

Reifenhäuser Cast Sheet Coating is part of the plastics extrusion–focused Reifenhauser Group. Sister company Reifenhäuser Reicofil, a global supplier of nonwoven lines, provided considerable support in developing Ultrathin Coating technology.

Even manufacturers who produce medical protective clothing and prefer to handle the coating process internally rather than importing the composites, may find it worthwhile to set up an in-house production facility, according to Reifenhäuser Cast Sheet Coating. The return on investment typically is less than 12 months, and less material input reduces consumption of raw materials, supporting sustainability initiatives, said the company.

You May Also Like