Amcor’s New 50-ml PET Bottle Goes with the Recycling Flow

New structural design keeps small PET bottles from slipping out of the recycling stream during sorting.

November 22, 2021

Amcor Rigid Packaging (ARP) has developed a solution to the problem of small polyethylene terephthalate (PET) bottles literally slipping through the cracks at recycling centers. The innovation is a bottle design that maximizes the collapsed container’s width. ARP announced the innovation on America Recycles Day: November 15, 2021.

The newly redesigned PET bottle collapses in a controlled way, becoming wide enough to move through the recycling process along with larger items. According to Amcor, the innovation will enable billions of small bottles to be recycled. The project is part of Amcor’s designed-to-be-recycled packaging effort and aligns with the company’s commitment to making all its packaging recyclable, compostable, or reusable by 2025.

The first application for the technology is a 50-ml PET bottle, the size airlines use to serve liquor. When these conventionally designed bottles are sent to a US material recycling facility (MRF), they tend to escape the flow of recyclable materials at the same time broken glass is filtered out.

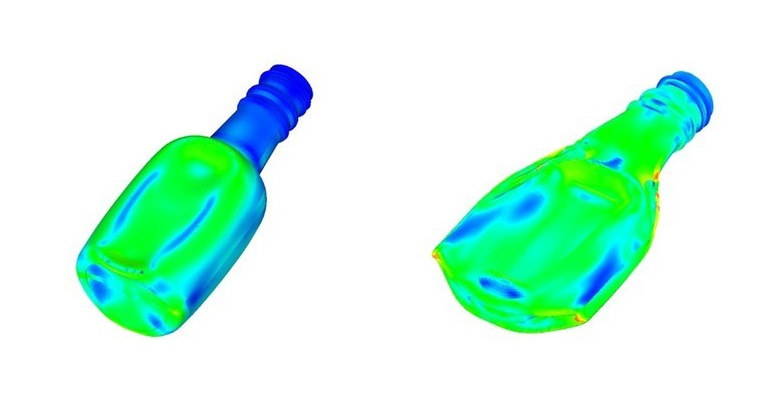

The new bottle design overcomes this problem by making the width of the collapsed bottle greater than 5 cm. This prevents the bottle from being lost during sorting at most US recycling facilities. The design, which includes intentional failure points, is based on guidelines from the Association of Plastic Recyclers.

“This discovery was made by the Amcor team when testing revealed that the bottles collapse in different ways,” said Terry Patcheak, VP of research, development, and advanced engineering at ARP, in a prepared statement.

“Our simulations demonstrated that when these tiny spirits bottles are designed to collapse in a specific way, fewer bottles actually fall through the cracks. The potential here is higher recyclability rates and more recycled content for multiple segments and materials.”

Amcor is performing Finite Element Analysis testing to better understand the dynamics of the new bottles during recycling. The company will also collaborate with recycling facilities to capture real-world data about the new bottle’s recyclability.

“We know that many small bottles are falling through screens in our MRFs designed to separate glass, so this is a major development — it allows these bottles to pass this step in the process and have the opportunity to be captured by the appropriate equipment downstream,” said Curt Cozart, chief operating officer at the Association of Plastic Recyclers. “At a time when the recycling industry is constrained by material supply, every additional pound diverted from waste makes a big difference.”

You May Also Like