Eastman launches a recyclable extrusion blowmolding resin for packaging applications

Eastman Chemical Co. has expanded its portfolio of resins with the addition of the Aspira One, a new recyclable PET polymer tailored specifically for extrusion blowmolding (EBM) processes and packaging applications such as clear handleware and large-size bottles.Eastman touts the new PET polymer as providing an "optimal balance of recyclability, product performance, production efficiency and aesthetics versus alternative polyester resins available to the EBM market."

October 12, 2012

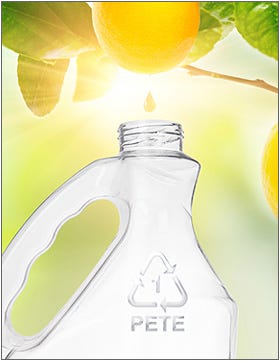

Eastman Chemical Co. has expanded its portfolio of resins with the addition of the Aspira One, a new recyclable PET polymer tailored specifically for extrusion blowmolding (EBM) processes and packaging applications such as clear handleware and large-size bottles.

Eastman touts the new PET polymer as providing an "optimal balance of recyclability, product performance, production efficiency and aesthetics versus alternative polyester resins available to the EBM market."

"We recognized we had a gap in our product line," Ron Salati, global market development manager, specialty plastics packaging for Eastman, told PlasticsToday. "We had the opportunity to round out our portfolio and offer extrusion blowmolders a new look for container resins."

The polymer is compatible in the PET recycle stream and carries RIC 1. In July, Aspira One received resin recognition from the Association of Postconsumer Plastic Recyclers (APR) for meeting the PET Bottle Critical Guidance Document protocol.

The polymer is compatible in the PET recycle stream and carries RIC 1. In July, Aspira One received resin recognition from the Association of Postconsumer Plastic Recyclers (APR) for meeting the PET Bottle Critical Guidance Document protocol.

Before, it was impossible to combine clarity, EBM manufacturing, and environmental responsibility for large containers, Eastman stated. The crystal-clear clarity of Aspira One allows consumers to see the contents of their packages, potentially providing valuable product differentiation and shelf appeal for brands.

For bottle performance, the material offers toughness and is free of BPA and halogens.

In contrast with other polyester resins for EBM, Aspira One is an amorphous, melt-phase produced material, according to Eastman. Aspira One pellets are not crystalline or solid-stated, they can be dried and processed at lower temperatures than other PET resins.

Another feature is that the crystallization of bottle flash regrind is not required, because Aspira One pellets are amorphous and thereby compatible with the regrind in a dryer setup. In addition, Aspira One does not melt fracture at high extrusion rates, giving it high clarity on all EBM platforms.

Salati said that the company is currently running trials and they anticipate several companies, including major global beverage brands, will begin using Aspira One starting in 2013.

"Everyone has been very accepting and we've gotten positive responses," he said. "Our product is always very desired in the market but the only negative was the issue around recyclability in the PET stream. With our new product, we're still keeping our proven technology, it's just now going to fit in the recycled stream, which is one of the desires customers have."

About the Author(s)

You May Also Like